As technology continues to advance at a rapid pace, the demand for compact and efficient electronic devices has surged. A significant innovation in this realm is the rigid flex PCB (Printed Circuit Board), which combines the best features of both rigid and flexible circuits, allowing for more complex, space-saving designs. According to a recent market research report by Fortune Business Insights, the global rigid-flex PCB market is projected to reach USD 15.32 billion by 2028, expanding at a CAGR of 10.85% from 2021 to 2028. This growth underscores the increasing reliance of industries, from consumer electronics to aerospace, on rigid flex PCBs to meet their design and performance requirements.

Choosing the right rigid flex PCB for your project is essential for ensuring optimal functionality and efficiency. Factors such as material selection, layer count, and manufacturer capabilities play crucial roles in determining the effectiveness of the final product. For instance, materials like polyimide and FR-4 are often employed to balance flexibility and thermal performance, essential for high-density applications. As highlighted in a report by IPC, the demand for higher layer counts in rigid flex designs has been on the rise, emphasizing the need for precision and reliability in selecting the appropriate manufacturing techniques. By carefully evaluating these considerations and leveraging industry insights, designers can maximize the potential of rigid flex PCBs in their projects.

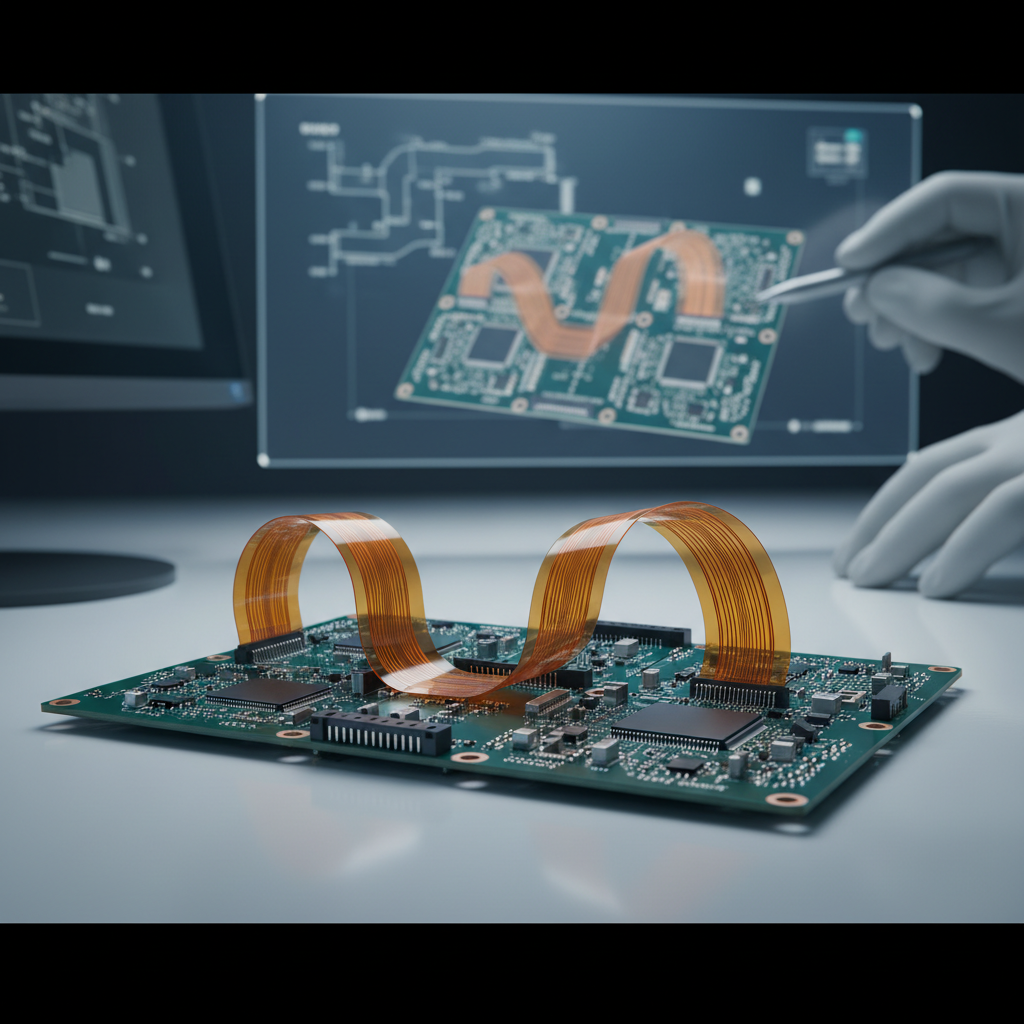

Rigid flex PCBs are a unique hybrid of traditional rigid and flexible printed circuit boards, designed to combine the durability of rigid circuits with the versatility of flexible circuits. Understanding the basics of rigid flex PCBs is crucial for effectively integrating them into your project. They typically consist of multiple layers of rigid and flexible materials, enabling them to bend and fit into compact spaces while maintaining functionality. This makes them ideal for applications in industries like aerospace, medical devices, and consumer electronics.

Rigid flex PCBs are a unique hybrid of traditional rigid and flexible printed circuit boards, designed to combine the durability of rigid circuits with the versatility of flexible circuits. Understanding the basics of rigid flex PCBs is crucial for effectively integrating them into your project. They typically consist of multiple layers of rigid and flexible materials, enabling them to bend and fit into compact spaces while maintaining functionality. This makes them ideal for applications in industries like aerospace, medical devices, and consumer electronics.

When selecting a rigid flex PCB for your project, consider its intended application. Factors such as size constraints, environmental conditions, and the complexity of the circuit design will significantly influence your choice.

Tip: Always communicate your project's specific requirements with your PCB manufacturer to ensure that the design meets both functional and regulatory standards.

Another important aspect is the assembly process. Rigid flex PCBs can streamline your manufacturing operations by reducing assembly times and minimizing the number of independent components.

Tip: Collaborate with your design team early in the process to identify potential challenges and optimize your PCB layout for better performance.

When selecting rigid flex PCB materials for your project, several key factors must be considered to ensure optimal performance and reliability. One of the primary considerations is the choice of dielectric materials, which directly affects the flexibility and miniaturization of the design. High-frequency applications benefit from materials with low dielectric constants, allowing for enhanced signal integrity even in tightly packed circuitry.

Additionally, the thermal performance of the rigid flex PCB is crucial. Materials with appropriate thermal conductivity will help manage heat dissipation, reducing the risk of component failure in demanding environments. Also, it's essential to evaluate the manufacturing capabilities and compatibility of the chosen materials with the production process, as this will impact both cost and timeline.

Understanding these factors can guide you in making informed decisions that align with industry trends and technological advancements anticipated between 2025 and 2027.

When selecting a rigid flex PCB, design considerations are crucial to ensure optimal performance. According to a report by the IPC (Association Connecting Electronics Industries), the right choice of materials can significantly affect the board's reliability and flexibility. For instance, using a polyimide substrate instead of traditional FR-4 can enhance thermal stability and allow for tighter bend radii, which is increasingly important in compact electronic designs. Additionally, the dielectric constant of the material impacts signal integrity; materials with low dielectric constants can help reduce signal loss and improve high-frequency performance.

Another essential factor is the layer stacking configuration. Research by TechNavio indicates that a well-designed stack-up that balances the rigid and flexible elements can minimize stresses at the interconnections. Utilizing specific adhesive layers that maintain flexibility while securely bonding the rigid sections can also prevent delamination during thermal cycling. Furthermore, incorporating vias in the right locations can enhance electrical connectivity without compromising the board's mechanical integrity. As the demand for lightweight and space-efficient electronic devices grows, these design considerations will be pivotal in achieving an efficient and reliable rigid flex PCB for your project.

When selecting a manufacturer for rigid flex PCB production, it’s essential to evaluate their capabilities thoroughly. Start by assessing their technology and equipment. Advanced machinery and the latest fabrication processes not only improve precision but also enhance the overall quality of the PCBs. A manufacturer that consistently invests in state-of-the-art technology is more likely to deliver products that meet the stringent requirements of modern electronic applications.

Another critical factor is the manufacturer's experience and track record. Look for companies that have successfully completed projects similar to yours and have a solid reputation in the industry. Customer reviews and case studies can provide valuable insights into their production capabilities and reliability. Additionally, consider the manufacturer's certification and compliance with industry standards. Certifications such as IPC and ISO can indicate a commitment to maintaining high-quality manufacturing processes, which can significantly impact your project’s success.

| Manufacturer Capability Dimension | Evaluation Criteria | Rating (1-5) | Comments |

|---|---|---|---|

| Experience in Rigid Flex PCB | Years of Experience in Production | 4 | Solid background with multiple projects. |

| Technology and Equipment | Availability of Advanced Machinery | 5 | State-of-the-art technology in place. |

| Production Capacity | Monthly Production Volume | 3 | Can handle moderate order sizes. |

| Quality Assurance | Certifications and Quality Control Processes | 5 | ISO certified with rigorous testing. |

| Customer Service | Responsiveness and Support | 4 | Prompt communication and helpfulness. |

| Cost Competitiveness | Pricing vs. Market Rate | 3 | Pricing slightly above average. |

When planning a rigid flex PCB project, understanding the cost factors involved is crucial for effective budgeting. The total cost of a rigid flex PCB will depend on multiple variables, including the complexity of the design, the materials used, and the manufacturing processes required. It's essential to create a detailed cost analysis that includes direct expenses such as fabrication, assembly, and testing, as well as indirect costs such as tooling and freight. By breaking down these costs, project managers can identify areas where savings can be made without compromising quality.

Moreover, allocating a budget for unforeseen expenses is essential in rigid flex PCB projects. Given the unique challenges associated with these types of circuits, including their delicate nature and specialized handling, unexpected costs may arise during production. Setting aside a contingency budget allows for flexibility and can help mitigate risks associated with production delays or revisions. Engaging with suppliers early in the process can also assist in getting accurate quotes and lead times, ultimately leading to a more efficient budgeting process.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |