Efficient quick turn PCB assembly is crucial for today’s fast-paced electronics industry. Designers often face tight deadlines that demand rapid production. The need for speed can sometimes lead to oversights. A rushed process might compromise quality. Each step in the assembly process must be handled with care.

Choosing the right manufacturer is vital. Not all companies can meet quick turn requirements effectively. Some might promise speed but fail in quality control. Working with a trusted partner can help avoid these pitfalls. Their expertise often ensures a smoother workflow. Mistakes are also less likely to occur with experienced hands.

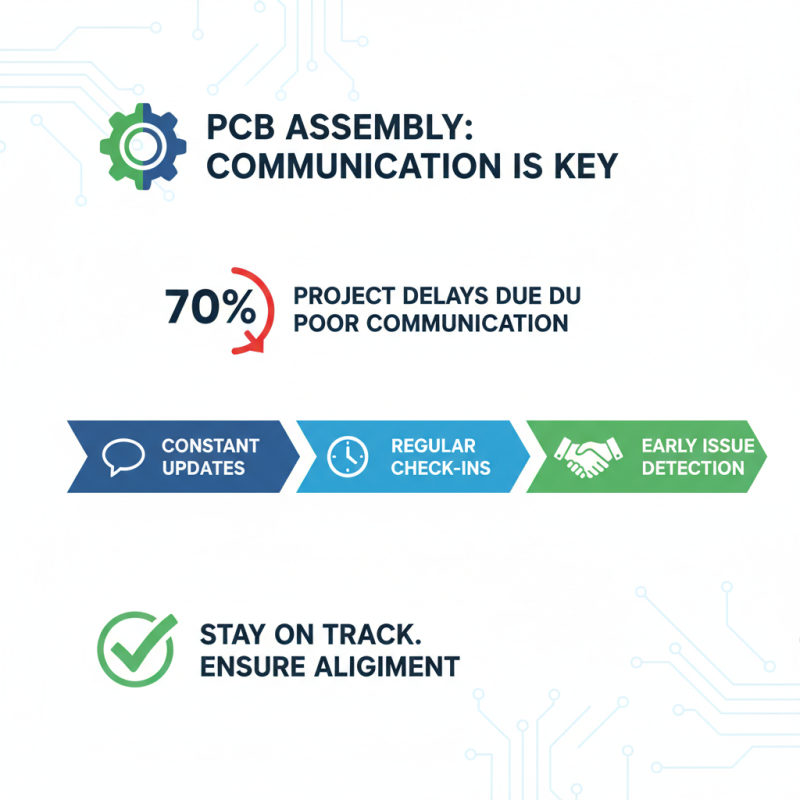

Communication is key throughout the quick turn PCB assembly process. Clear and consistent exchange of information helps address challenges quickly. Teams that collaborate efficiently can identify potential issues in advance. This proactive approach leads to better outcomes and fewer delays. Balancing speed with quality remains a constant challenge for many in the industry.

Quick turn PCB assembly is a method designed for rapid production of printed circuit boards. This process is ideal for prototypes or low-volume projects. It significantly reduces lead times compared to standard assembly methods. By streamlining manufacturing processes, designers and engineers can receive their PCBs faster, allowing for quicker iterations.

The benefits of quick turn PCB assembly are manifold. Teams gain flexibility when addressing design flaws or changes. The speed enables faster market entry, giving businesses a competitive edge. However, it’s essential to consider that rushing this process may lead to quality compromises. A delicate balance between speed and quality must be maintained. Proper communication with manufacturers is vital to ensure project specifications are met accurately.

Despite the advantages, challenges remain. Sometimes, sourcing components on short notice can be problematic. Unexpected delays can arise, impacting the timeline. Engaging closely with suppliers helps mitigate these risks. Quick turn assembly can revolutionize project timelines if done thoughtfully. Always reflect on the trade-offs to find the best solution for your specific needs.

This chart illustrates the time savings across different steps in the Quick Turn PCB assembly process. Businesses can significantly reduce design, prototyping, manufacturing, testing, and delivery times, enhancing overall project efficiency.

When it comes to quick turn PCB assembly, several key factors impact efficiency. The design phase plays a vital role. A well-optimized PCB layout can significantly reduce assembly time. Complex designs may require more steps, leading to longer production delays. It's essential to strike a balance between functionality and simplicity.

Materials selection is another critical factor. Using standardized components often speeds up assembly. Custom parts can introduce delays, especially if they are not readily available. Quality materials can also reduce defects, which eliminates the need for rework.

Tips: Collaborate early with your PCB assembler. This can lead to better design choices. Always verify component availability during the design phase. Keep communication lines open for faster adjustments.

In addition, the choice of assembly techniques is crucial. Automated processes typically enhance speed but may require upfront investment. Manual assembly can be slower, though it offers flexibility for custom projects. Evaluate your project needs carefully. Consider the trade-offs of speed versus cost. A well-rounded approach helps achieve efficient assembly without sacrificing quality.

Efficient PCB design plays a crucial role in achieving quick turnaround times. According to a recent industry report, 80% of delays in PCB assembly are due to design errors. Therefore, it's essential to prioritize a clean and organized layout. Keeping component placement logical and minimizing trace lengths can improve manufacturability and assembly speed.

Utilizing design rules check (DRC) tools is vital. These tools identify potential issues before production starts. By catching problems early on, you can save significant time and costs. Studies show that implementing DRC effectively can reduce costly redesigns by up to 30%. Simplicity in design can also enhance efficiency. Complex designs often lead to mistakes that delay timelines.

Another critical aspect is effective communication with your PCB manufacturer. Regular updates and clear specifications can bridge the gap often left in design handoffs. It’s not uncommon for designers to overlook small details, such as the type of finish or hole plating. Neglecting these factors can lead to misalignment and longer production times. Aim to create thorough documentation that captures every detail, no matter how small. This is crucial for achieving the fast turnaround you desire.

| Design Aspect | Best Practice | Impact on Turnaround Time |

|---|---|---|

| Schematic Design | Use standardized components | Reduces sourcing time |

| PCB Layout | Follow design rules strictly | Minimizes errors and reworks |

| Material Selection | Choose readily available materials | Speeds up production |

| Prototyping | Utilize rapid prototyping techniques | Accelerates testing and validation |

| Communication | Maintain clear communication with manufacturers | Avoids misunderstandings |

| Design Verification | Conduct thorough design reviews | Prevents delays in production |

When it comes to quick turn PCB assembly, selecting the right materials and technologies is crucial. According to a 2022 industry report, PCBs made with high-quality materials can reduce assembly time by up to 30%. This is vital for projects demanding fast turnaround. Advanced technologies like automated pick-and-place machines enhance speed. However, they require precise planning and understanding of production capabilities.

Tips: Always verify material compatibility with your design. Some materials may not bond well, leading to defects. Choose solder types that match your assembly process. It’s essential to communicate with your supplier about your specific needs. Cutting corners may save time, but it risks quality.

Emphasizing materials, consider FR-4 which is common and cost-effective. Yet, alternatives like Rogers might suit high-frequency applications better. Be aware that switching materials can complicate the assembly process. Balancing cost, quality, and speed requires careful thought. Each decision impacts the overall timeline of your project.

Effective communication is crucial in PCB assembly projects. According to industry reports, around 70% of project delays stem from poor communication. Team members must share updates constantly. Regular check-ins can help catch issues early. This ensures everyone is on the same page regarding timelines and expectations.

When managing workflows, use project management tools to track progress. These platforms help identify bottlenecks quickly. Implementing a clear feedback loop is essential. Encourage team members to voice concerns promptly. Awareness of potential obstacles can save valuable time.

Another tip focuses on documentation. Keep a central repository of documents related to the project. This practice reduces confusion and miscommunication. Ensuring all members access updated files is vital. Additionally, celebrate small wins. Acknowledging progress boosts morale and fosters collaboration. Reflecting on workflow challenges will lead to improved efficiency in future projects.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |