In the rapidly evolving field of electronics, selecting the right services for PCB manufacturing and assembly is crucial for the success of any project. Experts agree that the quality of printed circuit boards directly impacts the performance and reliability of electronic devices. John Smith, a leading authority in the PCB industry, emphasizes, "The choice of PCB manufacturing and assembly services can make or break your project; it’s essential to consider both quality and capability."

When embarking on a new project, understanding the various factors involved in PCB manufacturing and assembly can be overwhelming. Different manufacturers offer varying levels of expertise, technology, and support, making it imperative to thoroughly evaluate options based on specific project needs. A well-chosen partner not only contributes to the efficiency of production but also enhances the overall product quality.

As we delve deeper into this topic, we’ll explore critical considerations that can help guide your decision-making process. From assessing the technical capabilities of manufacturers to ensuring compatibility with your design requirements, navigating the landscape of PCB manufacturing and assembly services is key to achieving your project goals successfully.

When embarking on a printed circuit board (PCB) project, understanding your specific requirements is crucial. Begin by defining the purpose of the PCB. Consider factors such as the electronic components it will house, the environment in which it will operate, and the expected lifespan of the product. This step ensures that the manufacturing techniques and materials chosen align with the intended application, be it automotive, industrial, or consumer electronics. By gathering this information early, you can streamline the design process and avoid costly revisions later on.

Next, take into account the technical specifications essential for your project. This includes the size of the PCB, the number of layers, and the type of surface finish. Additionally, investigate the desired level of complexity, such as the use of high-frequency signals or dense component placement. Customizing these specifications based on your project can significantly impact the manufacturing process and assembly efficiency. Clear communication of these requirements to your chosen service provider is key, ensuring they can deliver a product that meets your expectations while adhering to regulatory standards.

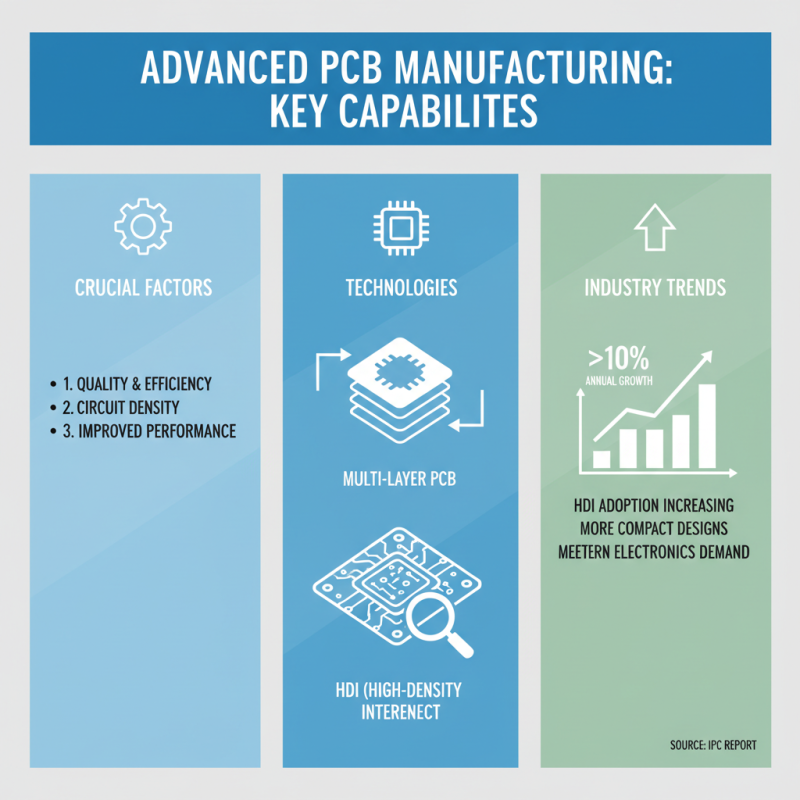

When evaluating PCB manufacturing capabilities and technologies, it is crucial to consider several key factors that can significantly impact the quality and efficiency of your project. Advanced manufacturing technologies, such as multi-layer PCB fabrication and HDI (High-Density Interconnect) capabilities, allow for greater circuit density and improved performance. A report from IPC indicates that the adoption of HDI technology has been increasing steadily, with a projected growth rate of over 10% annually in the next few years. This trend demonstrates the industry's push towards more compact and efficient designs, essential for meeting the demands of modern electronics.

Additionally, assessing the manufacturing capabilities of a potential service provider involves looking into their equipment and processes. For instance, manufacturers utilizing automated inspection technologies, such as AOI (Automated Optical Inspection), can ensure higher levels of accuracy and reduce the likelihood of defects in the final product. According to a study by Derek D. and Lam C., companies that implement robust quality control measures, including automated inspections, report a decrease in defect rates by as much as 30%. This ensures not only a reliable product but also a reduction in costs associated with rework and warranty claims. Evaluating these capabilities is vital in selecting a partner that aligns with the technical requirements and quality standards of your project.

When selecting PCB manufacturing and assembly services, understanding lead times is crucial for efficiently managing your project timeline. According to a report from IPC, the average lead time for PCB assembly can vary significantly based on the complexity of the assembly and the technologies used. Standard lead times typically range from 2 to 6 weeks, with more complex assemblies or prototyping requiring longer durations. This variability can impact project schedules, making it essential to discuss your specific timelines with potential service providers to ensure they align with your project deadlines.

Furthermore, it's important to compare different assembly services based on their lead times and capabilities. A study from the Institute for Printed Circuits indicates that manufacturers who utilize automated assembly technologies can often reduce lead times by 30% compared to those reliant on manual processes. When evaluating services, consider not only the quoted lead times but also their capacity for expedited orders and their overall throughput. By thoroughly assessing these factors, you can make a more informed decision that aligns with your project’s needs and ensures timely delivery of your PCBs.

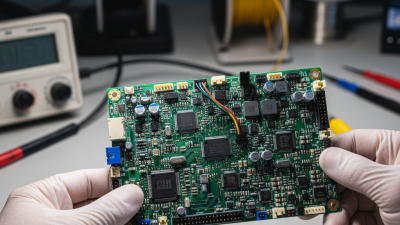

When selecting PCB manufacturing and assembly services, assessing quality assurance and certifications is imperative for ensuring reliability and performance. Quality assurance processes, such as thorough inspections and testing, help identify any potential defects early in the production cycle. Accredited certifications, such as ISO 9001, indicate that the manufacturer adheres to international quality management standards. A facility that maintains these certifications demonstrates a commitment to producing high-quality products and continuously improving processes.

In addition to standard certifications, specialized certifications such as IPC-A-600 or IPC-A-610 are essential when dealing with printed circuit boards. These certifications ensure that the manufacturer follows established guidelines for board integrity and assembly quality. Reviewing a provider's quality assurance protocols and certifications not only provides a level of assurance regarding their capabilities but also serves as a benchmark for their overall operational excellence. Evaluating these aspects before making a decision can significantly impact the success and reliability of your project.

When selecting PCB manufacturing and assembly services, it is essential to evaluate their customer support and post-production services. A responsive and knowledgeable customer support team can significantly enhance the overall experience. Look for companies that offer multiple communication channels, such as phone, email, and live chat. This ensures that you can easily reach out for assistance with inquiries or issues that may arise during the project. A commitment to customer satisfaction can be demonstrated through timely responses and effective problem-solving capabilities, which are crucial for maintaining deadlines and addressing potential concerns.

Post-production services are equally important, as they play a vital role in the long-term success of your project. Consider manufacturers that provide a range of post-production support, including testing, inspection, and quality assurance. These services ensure that the final product meets your specifications and industry standards. Furthermore, reliable companies often offer support for revisions or modifications, should you need to make adjustments after the initial run. By focusing on customer support and comprehensive post-production services, you can choose a PCB manufacturer that will not only meet your immediate needs but also support your project throughout its lifecycle.

| Criteria | Rating (1-5) | Comments |

|---|---|---|

| Customer Support Responsiveness | 4 | Generally quick responses within 24 hours. |

| Technical Expertise | 5 | Highly knowledgeable staff, able to provide valuable insights. |

| Post-Production Support | 4 | Offers assembly, testing, and troubleshooting services. |

| Delivery Timeliness | 3 | Delivery sometimes delayed but usually within a reasonable timeframe. |

| Cost Competitiveness | 4 | Pricing is reasonable compared to industry standards. |

| Quality of Work | 5 | High-quality PCBs with minimal defects reported. |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |