Choosing the right rigid flex PCB for your project is crucial for its success. John Doe, a leading expert in PCB design, once said, "The right choice can make or break your project." Rigid flex PCBs combine the best of both worlds: flexibility and durability. They can fit into tighter spaces while maintaining performance.

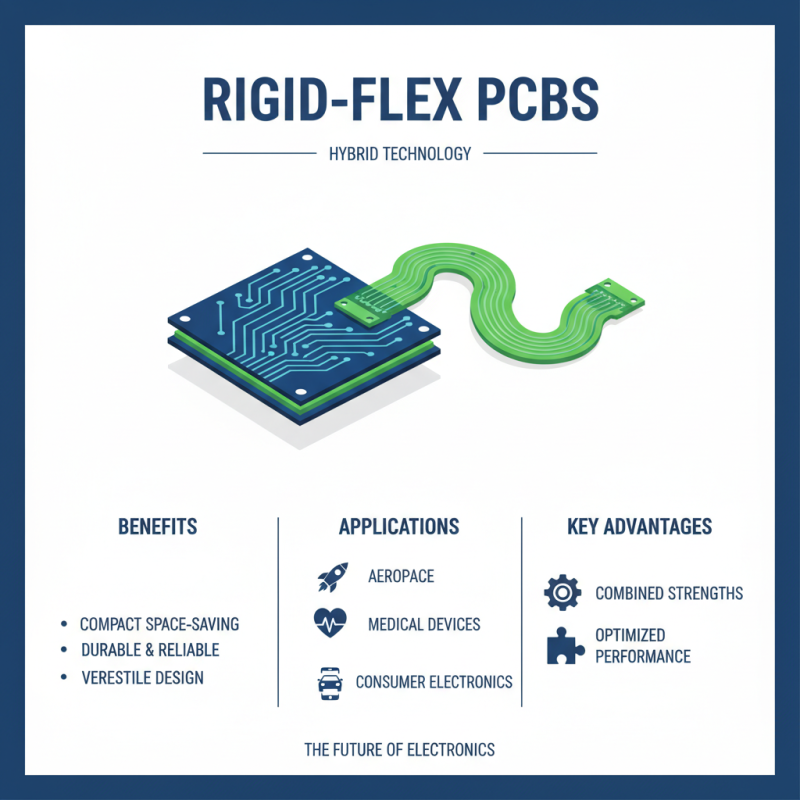

Understanding your project's unique needs is key. Consider factors like size, weight, and electrical performance. Rigid flex PCBs can be custom-designed for specific applications, from medical devices to aerospace technology. This versatility increases their importance.

However, selecting the wrong type could lead to failure. Not all rigid flex PCBs are the same. The density of components, layer count, and flexing points must match your specifications. It’s easy to overlook these details amid the excitement of new projects. Taking the time to evaluate options will pay off in the long run.

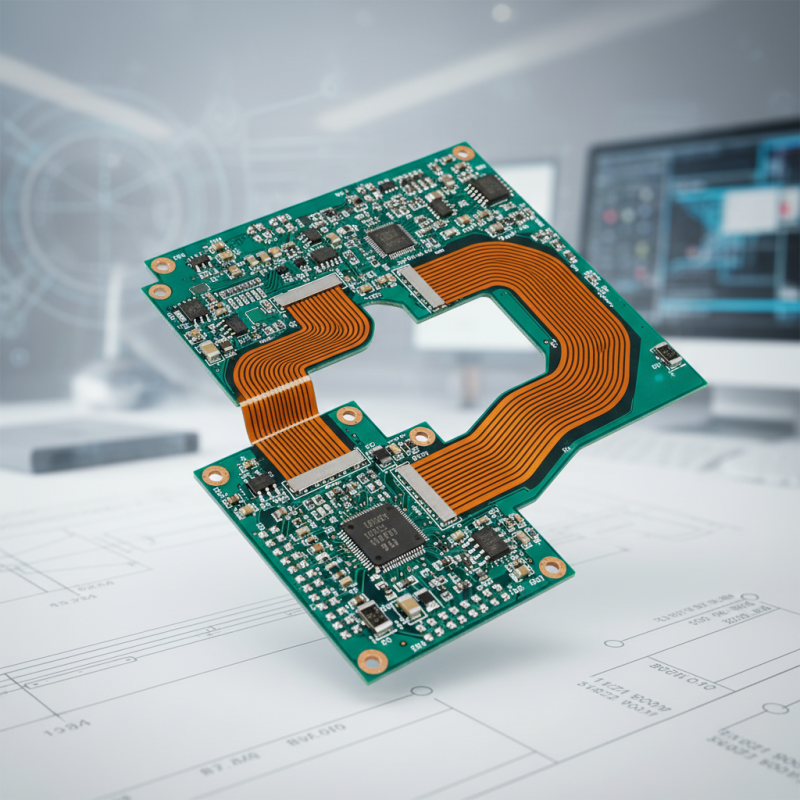

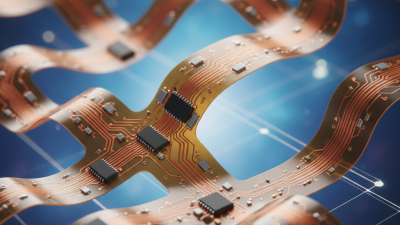

Rigid flex PCBs are a hybrid of rigid and flexible circuits. They combine the best of both worlds. This technology is gaining popularity across various industries. From aerospace to medical devices, these PCBs offer unique solutions. Their compact nature saves space, which is crucial in many applications.

When selecting the right rigid flex PCB, consider your project's needs. Focus on size, weight, and durability. Assess your environmental conditions. Heat, moisture, and vibration can affect performance. Make sure the PCB can withstand these factors. It's also essential to communicate your specific requirements. Designers often have to make compromises. Understanding these trade-offs can save time and resources.

**Tip:** Always prototype before finalizing your design. This phase helps identify potential issues early on. Testing ensures functionality meets your expectations. Another tip is to collaborate closely with your PCB manufacturer. Their expertise can guide you through the process. Keep an open mind to suggestions. Perfection is the goal, but flexibility in design can lead to better outcomes.

Choosing the right rigid flex PCB for your project can be challenging. You need to consider several key factors. Start with the application requirements. Different projects demand various performance levels. Some may need flexibility, while others require durability. Understand the specific needs of your device.

Next, evaluate the environmental factors. Will the PCB face extreme temperatures or humidity? This decision impacts material selection. For example, high temperatures may require specific substrates. Additionally, think about mechanical stress. Rigid areas need support while flexible areas require adequate bending capabilities.

Another important point is design complexity. Complicated designs can lead to higher costs and longer production times. Evaluate whether the design meets efficiency criteria. Simplicity often leads to better reliability.

Finally, don’t overlook the importance of testing. Prototyping can reveal flaws early in the design process. It’s better to identify issues now rather than later. These reflections can guide you in making an informed choice.

Choosing the right materials for your rigid flex PCB is crucial. The materials can affect performance and reliability. Common choices include polyimide and FR-4. Polyimide is flexible and offers excellent heat resistance. It can endure harsh environments well. On the other hand, FR-4 is less flexible but often more cost-effective.

When evaluating material types, consider the application. For high-frequency designs, specific materials work better. For example, materials with low dielectric constants can minimize signal loss. However, they might be more expensive. It's essential to balance performance and budget.

Another factor is thickness. Thicker materials can add durability but reduce flexibility. This may limit routing options. You might find that thicker materials also increase weight. Think about how this affects your design. Each project requires a careful decision-making process. Consider potential trade-offs along the way.

| Material Type | Dielectric Constant (Dk) | Thermal Conductivity (W/m·K) | Temperature Resistance (°C) | Typical Applications |

|---|---|---|---|---|

| FR-4 | 4.2 | 0.3 | 130 | General electronics |

| Polyimide | 3.5 | 0.2 | 260 | Aerospace, automotive |

| PTFE | 2.1 | 0.25 | 200 | High-frequency applications |

| Bamboo | 3.3 | 0.23 | 150 | Eco-friendly applications |

When selecting a rigid flex PCB, focus on specific design requirements. Consider the size and layout of your project. The dimensions will dictate the type of materials you need. Smaller designs require more compact PCBs, while larger projects might offer flexibility in layout.

Understand the electrical specifications as well. Voltage requirements and current loads should match the PCB's capabilities. Materials used in the PCB can affect performance. For example, certain materials may resist heat or environmental conditions better than others.

Additionally, think about how the PCB will be used. Is it for a mobile device or an industrial application? Each use case has distinct needs. If your project is rushed, you may overlook crucial details. This could lead to future complications. Reflecting on your requirements can help improve the decision-making process. Choosing wisely will save time and costs later.

When considering rigid flex PCBs, cost is a critical factor. Choosing the right type can affect your project’s budget. Prices can vary based on materials, design complexity, and manufacturing processes. Keep in mind that cheaper options may compromise quality. This could lead to higher costs in the long run due to repairs or replacements.

Tips: Always request multiple quotes. Compare them carefully. Look for hidden costs in the fine print.

Additionally, analyze the long-term benefits of your choice. Sometimes, investing more upfront can lead to better performance and durability. Failure to consider this can result in unexpected costs. Review your project requirements thoroughly to ensure you’re making an informed decision.

Tips: Don’t overlook prototyping. Testing can reveal important design flaws early. It’s often worth the expense if it saves you from larger issues later.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |