Choosing the right circuit board manufacturing process can significantly impact project success. The global PCB market reached $75 billion in 2022, according to reports by market research firms. This growth indicates the rising importance of circuit board manufacturing in various fields.

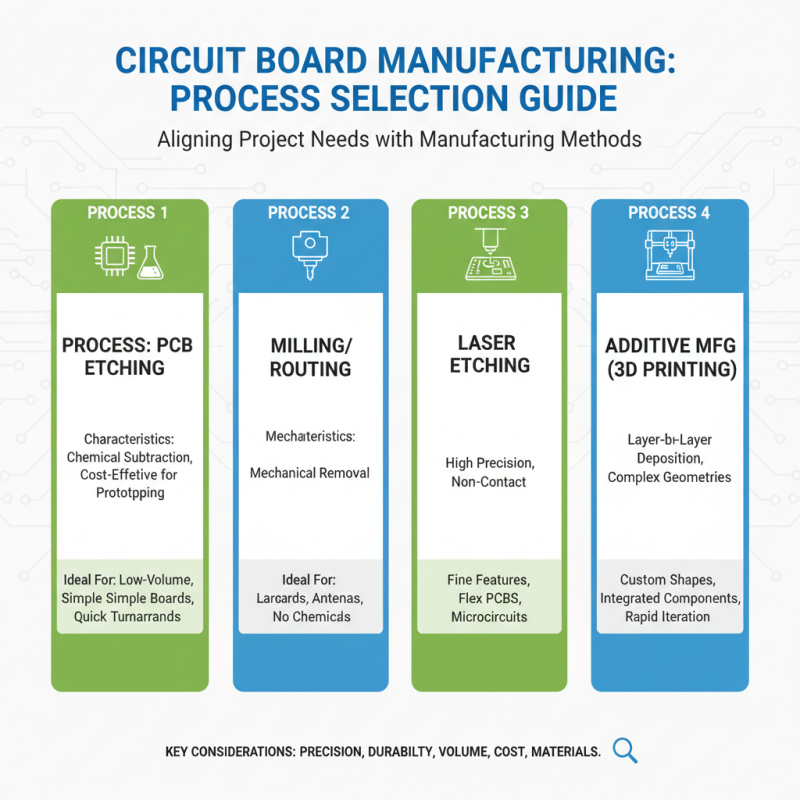

Several factors influence the selection of a manufacturing process. These include project complexity, cost constraints, and production volume. For instance, low-volume runs may benefit from prototyping methods like additive manufacturing. High-volume projects often align with traditional methods, such as photolithography. Many companies may overlook these options, leading to inefficiencies and higher costs.

Additionally, technology advancements continuously reshape the industry. New materials and techniques emerge, challenging established practices. Therefore, carefully evaluating available options becomes crucial. A misstep in choosing the right method can hinder a project’s timeline and budget. It’s essential to weigh each process's strengths and weaknesses.

When choosing a circuit board manufacturing process, understanding the options is crucial. There are various methods, including traditional subtractive processes and modern additive technologies. A report by IPC shows that 35% of manufacturers prefer standard processes for PCB production. These methods typically use copper layers that are etched away to create circuits. It's a reliable approach but may lead to material waste.

In contrast, additive manufacturing is gaining traction. This technique builds circuits layer by layer. Research indicates that this can reduce production time by 30% compared to traditional methods. However, it often requires specialized equipment that some manufacturers might not have. Industry experts point out that not every project is suitable for this innovative approach.

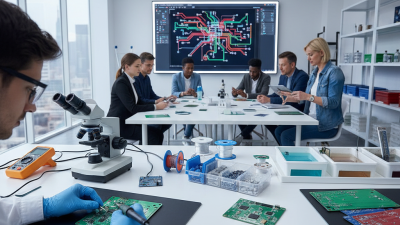

Moreover, surface mount technology (SMT) is widely adopted due to its efficiency. Reports indicate that SMT accounts for 70% of PCB assemblies today. This method allows for compact designs and faster assembly times. Yet, it can pose challenges regarding thermal management. Engineers need to ensure that components do not overheat. Balancing these factors is key to selecting the right process for your project.

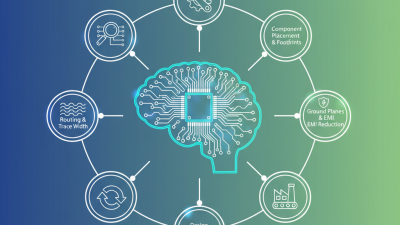

When selecting a manufacturing process for circuit boards, several key factors come into play. Material choice is critical. Certain materials can affect the board's performance, longevity, and cost. For example, FR-4 is popular for its balance of cost and performance, yet it may not be ideal for high-frequency applications. According to industry reports, approximately 45% of PCB failures stem from material-related issues.

Design complexity is another crucial factor. Higher complexity requires more advanced processes. This can lead to higher costs and longer lead times. In fact, research indicates that 30% of projects overshoot budgets due to unforeseen design complexities. It’s essential to accurately assess the design before moving forward. Skimping on this assessment can lead to delays and increased expenses.

Production volume also influences the choice of manufacturing processes. Low-volume runs can benefit from flexible options like rapid prototyping. However, high-volume productions may necessitate automated processes for efficiency. Studies show that production efficiency can improve by up to 25% with the right process selection. It’s important to reflect on these elements to ensure the manufacturing choice aligns with project goals.

| Factor | Description | Importance Level |

|---|---|---|

| Volume Production | Consider the number of units you need to produce. Higher volumes often lower per-unit costs. | High |

| Board Complexity | Determine the design complexity including the number of layers and components. | Medium |

| Lead Time | Assess how quickly you need the boards manufactured. Different processes have varying lead times. | High |

| Material Type | Identify the materials needed for the boards, which can affect the manufacturing process choice. | Medium |

| Cost Constraints | Consider your budget for manufacturing, including setup and production costs. | High |

| Technology Requirements | Determine if specialized technology is required for your product, which may limit choices. | Medium |

When selecting a circuit board manufacturing process, it's crucial to weigh the advantages and disadvantages of each method. For instance, traditional through-hole technology offers strong connections. This is beneficial for high-stress applications. However, this method can be costly and time-consuming. Production times may increase significantly for larger projects.

On the other hand, surface mount technology (SMT) provides a different set of benefits. SMT allows for smaller and lighter designs. This process reduces the overall space needed on the circuit board. Yet, one challenge is the potential for overheating issues. The delicate components can be harder to solder properly. It requires a keen eye and skilled technicians.

In addition to these techniques, the choice of materials plays a critical role. Many options exist, but not all are compatible with every process. Understanding the project’s requirements is key. Some materials may lead to unexpected challenges. These hurdles underline the importance of thorough planning and ongoing adjustments during production.

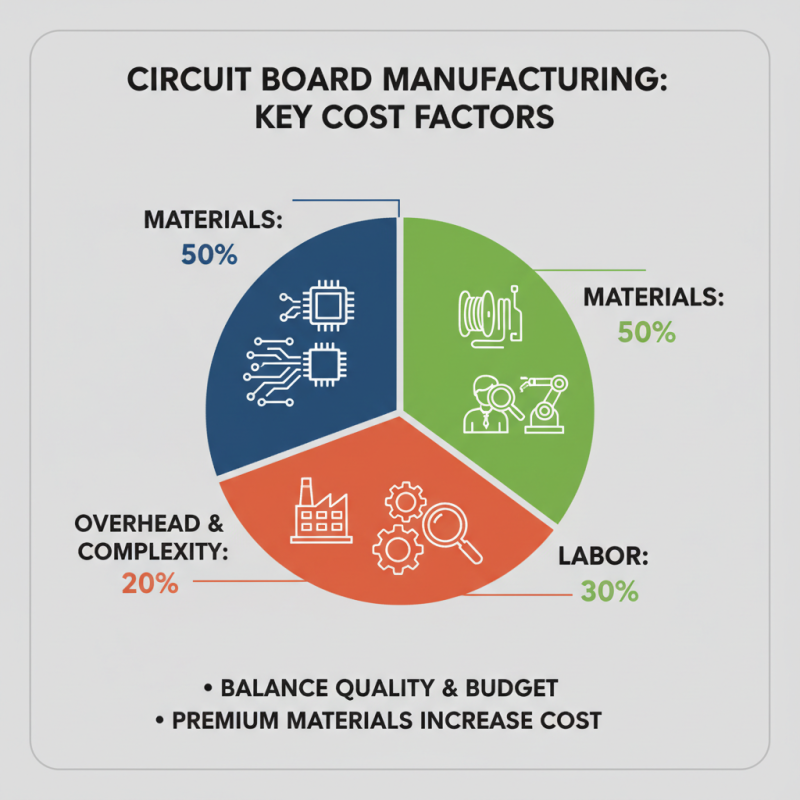

When choosing a circuit board manufacturing process, cost is a critical factor. A recent industry report found that materials account for approximately 50% of the total production cost. Other significant expenses include labor and overhead, which can add up quickly. For instance, a highly detailed board may require premium materials, pushing costs higher. It's crucial to balance quality and budget here.

Quality assurance measures also play a vital role. High-quality boards often lead to fewer defects and longer lifespans. According to a PCB industry analysis, manufacturers who invest in rigorous quality checks see a 30% reduction in return rates. However, achieving top quality can drive up costs, which is a common dilemma.

Lead time cannot be ignored either. A short lead time can mean higher prices. Some manufacturers expedite processes for a fee. Alternative manufacturers may offer longer lead times but lower prices. Evaluating each option's balance of cost, quality, and time is essential. It requires careful thought. The right decision hinges on project needs and acceptance of potential risks.

Choosing the right circuit board manufacturing process can be daunting. Each project has unique requirements. It is crucial to align these needs with the suitable manufacturing method. Consider the specifications first. Are high precision and durability essential? Then, look for processes that can meet those criteria.

Cost is another factor to ponder. Some methods can be expensive, while others are more budget-friendly. Balancing quality and cost can be tricky. It's wise to revisit your initial budget and adjust if necessary. Additionally, think about production volume. Low-volume projects may benefit from simpler processes. High-volume projects might require more complex techniques.

Reviewing each option is vital. Not every process suits a project’s needs. An ideal choice must accommodate both technical specifications and financial constraints. There may be instances where the initial decision does not yield expected results. Regular assessment and willingness to adapt are key to successful manufacturing.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |