In the rapidly evolving world of electronics, multi circuit boards play a crucial role. These boards are compact yet powerful. They enable the integration of numerous functions into a single unit. This design reduces space and weight in devices, which is essential for portable technology.

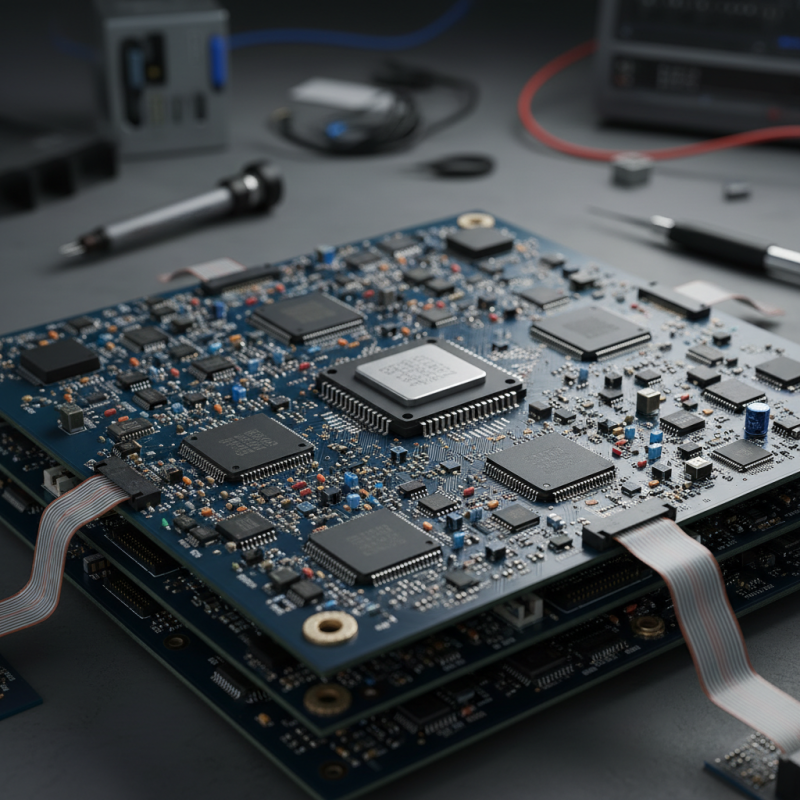

Modern gadgets often rely on multi circuit boards to enhance functionality. For instance, smartphones and laptops utilize complex multi circuit boards for processing. These boards help in managing power efficiently while maintaining performance. The intricate design often leads to challenges in manufacturing. There can be issues like heat dissipation and signal integrity. These complications remind us that innovation requires constant refinement.

As technology advances, the importance of multi circuit boards continues to grow. However, the complexity of these boards raises questions. How do we ensure reliability and ease of repair? Balancing performance with maintainability remains a significant challenge for engineers. Continuous improvements and thoughtful designs are needed to address these issues.

Multi Circuit Boards (MCBs) are integral to modern electronics. They refer to boards with multiple interconnected circuits. These boards can accommodate diverse electronic components in a compact space. This design reduces size and weight, which is crucial for portable devices.

The functionality of MCBs extends beyond mere space-saving. They enhance signal integrity and reliability. By minimizing the distance between components, MCBs improve performance. Thermal management is also a factor. Heat generated by components can quickly dissipate, preventing damage. However, designing MCBs is not without challenges. Layout complexity can lead to manufacturing errors.

Moreover, the testing phase can be time-consuming. Every circuit must be thoroughly checked for faults. Engineers must strike a balance between complexity and ease of production. In some cases, over-engineering can complicate repairs. Reflection on these aspects is vital to ensure effectiveness. Real-world applications highlight the importance of optimizing MCB designs for both functionality and simplicity.

Multi circuit boards play a critical role in modern electronics. They allow for complex interconnectivity in devices that demand high performance. According to a report by Research and Markets, the global PCB market is expected to reach $80 billion by 2026. This growth highlights the increasing reliance on multi circuit boards.

These boards enhance electronic performance by reducing the size of devices while maintaining efficiency. Multi circuit designs help in minimizing signal loss and improving heat dissipation. For instance, industry data shows that using multi-layer boards can lead to a 30% improvement in signal integrity compared to single-layer boards. This is crucial for devices like smartphones and laptops, where space and performance are at a premium.

**Tip**: Always consider the layout intricacies when designing multi circuit boards. A well-planned layout can prevent issues like crosstalk.

However, the complexity of these designs can lead to manufacturing challenges. Errors in routing or layer alignment can affect performance. Companies need to implement stringent quality control measures. Good design software can also help visualize potential problems before production.

**Tip**: Regular training for engineers on the latest PCB techniques is essential. Staying updated can mitigate common pitfalls in design.

Multi circuit boards are becoming increasingly important in modern electronics. They offer several advantages that enhance the functionality and efficiency of devices. With the rise of compact and complex designs, multi circuit boards help integrate multiple circuits into a single board. This saves space and simplifies connections, leading to a more streamlined product.

A key benefit is the reduction in manufacturing costs. Fewer boards mean less material and labor. However, the design complexity can lead to potential errors. Engineers must invest extra time in the design phase to avoid these pitfalls. Prototyping and testing are essential to ensure reliability.

Multi circuit boards (MCBs) have become integral in the electronics industry. In smartphones, MCBs are essential for efficient space utilization. The average smartphone now contains over 100 components, packed tightly on MCBs. This design allows for increased functionality without making devices bulkier.

In automotive applications, MCBs are crucial. Electric vehicles (EVs) often require complex circuitry to manage power distribution and battery performance. Reports indicate that up to 50% of the value of modern EVs lies in their electronics. This reliance on MCBs highlights their importance in ensuring vehicle efficiency and safety.

Medical devices also rely heavily on multi circuit boards. They often face strict regulatory standards. Reports show that MCBs in medical devices must maintain high reliability to ensure patient safety. However, the challenge is maintaining performance under rigorous conditions. The need for innovation in MCB design is critical to meet these demands effectively.

| Application Area | Description | Benefits | Key Features |

|---|---|---|---|

| Consumer Electronics | Used in devices like smartphones, tablets, and laptops. | Compact size and integration of multiple functions. | High density, multi-layer construction. |

| Automotive Electronics | Supports systems like infotainment, navigation, and security. | Enhanced reliability and performance under extreme conditions. | Durability, thermal management capabilities. |

| Telecommunications | Used in routers, switches, and data transmission devices. | Faster data processing and minimal signal loss. | High-speed connectivity, optimized layouts. |

| Medical Devices | Found in diagnostic machines and patient monitoring systems. | Critical for precision and reliability in healthcare. | Bio-compatibility, electrical isolation. |

| Industrial Automation | Supports machinery controls and robotic systems. | Increased efficiency and reduced downtime. | Resistant to environmental factors, modular designs. |

Multi circuit boards are revolutionizing the electronics industry. These boards allow for compact designs while accommodating complex functionalities. As technology advances, their importance grows. We see a shift towards higher integration and miniaturization, especially in smartphones and wearable devices.

Future trends highlight innovations like flexible and printed circuit boards. These designs can bend and adapt to various shapes, enhancing versatility. Fabrication methods are evolving too, using materials that reduce weight and increase strength. However, challenges remain. Ensuring reliability under stress and thermal conditions is critical.

Sustainability is also a key factor. The push for eco-friendly materials is becoming stronger. Many manufacturers are exploring biodegradable options. Still, the balance between performance and environmental impact isn’t easy. As innovations continue, the path forward may not be entirely clear, but the direction is undeniably promising.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |