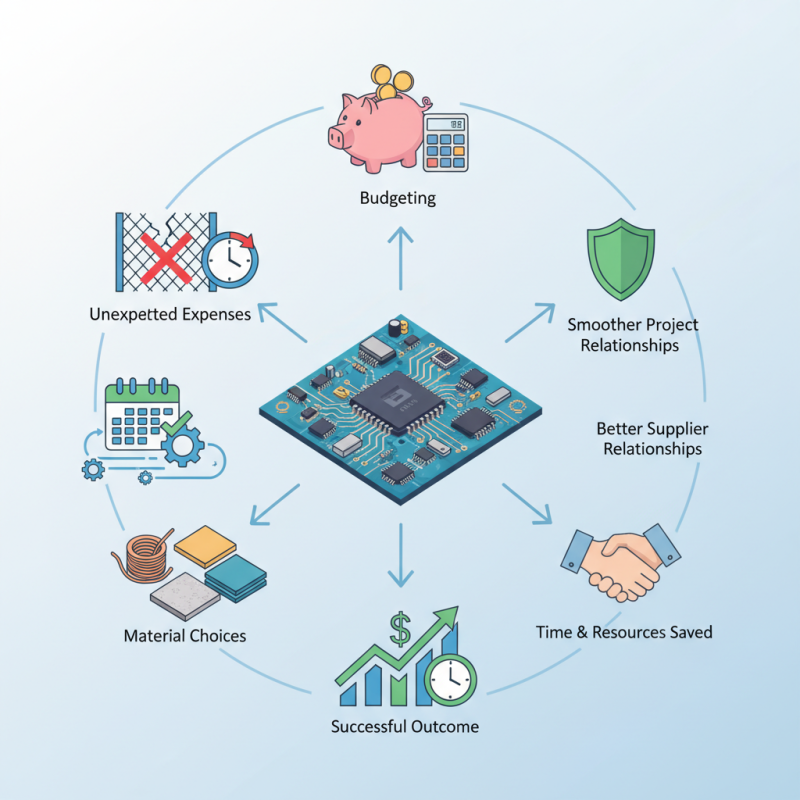

In the fast-evolving world of electronics, understanding the importance of a PCB quote is crucial. According to a recent report by the Electronics Industry Association, over 70% of project delays are linked to budgeting and sourcing issues. A precise PCB quote helps clarify costs and timelines, ensuring smoother project execution.

Tom Green, a renowned PCB design expert, emphasizes, "Without a proper PCB quote, projects can quickly spiral out of control." This highlights the need for accurate estimations early in the design process. Many engineers overlook this step, leading to unexpected expenses and extended timelines.

Obtaining a detailed PCB quote not only aids in financial planning but also influences material choices. Each component's cost can drastically affect the overall project budget. As a result, engineers must communicate effectively with suppliers. This prevents miscalculations and fosters better relationships. Embracing the practice of getting quotes early on can save both time and resources, promoting a more successful outcome.

Getting a PCB quote is a crucial step in electronics development. A detailed quote provides insights into costs, timelines, and capabilities. In a recent report by IPC,

70% of electronics projects experience delays due to budget overruns.

Accurate quotes can help avoid this pitfall.

When you receive a PCB quote, you gain visibility into materials and processes.

Many engineers overlook this step, leading to unexpected expenses later. It’s essential to know if the quoted materials are high quality or cost-effective.

A study from TechInsights revealed that

60% of prototypes fail due to poor component choices.

Without a comprehensive quote, decision-making becomes risky. Sometimes,

designers rush into production without assessing budget impacts.

A well-detailed quote should highlight potential trade-offs between speed and quality. Understanding the full picture helps teams align project goals and manage expectations.

Obtaining a PCB quote is crucial for any electronics project. A detailed quote includes essential components that significantly affect project outcomes. Price per unit, material specifications, and turnaround times are key elements. For instance, the average cost for high-quality PCBs can range from $1 to $10 per unit, depending on complexity and volume. Understanding these variables helps in budgeting and aligning with project timelines.

Another important aspect is the specification details. Designers need to know layers, thickness, and finish types. A report from IPC states that nearly 35% of delays in PCB production arise from unspecified requirements. Factors like lead time impact production, often requiring 2 to 6 weeks. Quoting processes can also reveal potential manufacturing challenges, aiding in risk assessment. Certain designs might be costlier if they include intricate traces or via designs.

Moreover, it's essential to stay informed about industry pricing trends. Recent data indicates a 15% increase in the average cost of PCB materials over the last year. This inflation must be reflected in quotes to avoid budget overruns. A well-prepared quote is not just a number; it is a reflection of project viability and strategic planning. Missteps in the quoting phase can lead to costly revisions and project delays.

When working on an electronics project, obtaining a PCB quote is crucial. Several factors can influence the variability of these quotes. For instance, the complexity of the design plays a significant role. A simple circuit board may cost less than one with intricate pathways and multiple layers. Even minor adjustments can lead to price fluctuations. Design intricacies often require additional manufacturing steps, which can increase costs significantly.

Material selection is another critical element. The type of substrate used can impact durability and performance. Standard materials are typically cheaper, while specialized materials can drive up the price. Additionally, aspects like the finish of the circuit board and the required trace width matter. Tight trace specifications may necessitate advanced techniques, adding to the total cost.

Lead times also affect quotes. Need it fast? That could mean a higher price tag. Balancing quality and cost can be a tricky endeavor. You might find cheaper options, but they may not meet your standards. It’s essential to reflect on these factors to ensure your project stays within budget while meeting its technical needs. Understanding these influences is key to making informed decisions.

| Parameter | Description | Impact on Cost |

|---|---|---|

| Board Size | Dimensions of the PCB in mm (e.g., 100x100) | Larger boards usually cost more due to material and handling |

| Layer Count | Number of conductive layers (e.g., 2-layer, 4-layer) | More layers increase manufacturing complexity and expense |

| Material Type | Type of material used for the PCB (e.g., FR-4, Rogers) | Special materials can significantly raise costs |

| Surface Finish | Coating on copper pads (e.g., ENIG, HASL) | Different finishes have varying costs and lead times |

| Quantity | Number of PCBs required | Higher quantities can lower cost per unit |

| Lead Time | Timeframe for production (e.g., 5 days, 2 weeks) | Shorter lead times typically incur higher costs |

| Testing Requirements | Quality control tests (e.g., functional testing) | Extensive testing adds to manufacturing costs |

| Design Complexity | Complex designs with tight tolerances | More complex designs lead to higher fabrication costs |

Getting a precise PCB quote is critical for any electronics project. A well-prepared request can significantly affect project timelines and costs. In fact, a survey by the IPC (Institute for Printed Circuits) revealed that inaccurate quotes can lead to budget overruns of up to 30%. Collecting all necessary information on your project details is essential to avoid surprises later.

When requesting a quote, provide specific details about your PCB design, dimensions, and layers. Include details about materials and the expected production volume. According to a report from PCB Tech, 45% of engineers reported that incomplete quotes slowed down their projects. Focus on conveying clear technical specifications. Precision is key; vague requests lead to vague responses.

Consider the turnaround time as well. A rush job may incur hidden costs. Delays in PCB production can arise from misunderstanding requirements. Some projects have inflated timelines by weeks due to insufficient initial quotes. A detailed request sets clear expectations, reducing the potential for miscommunication or errors. Think carefully about what your project truly needs versus what is feasible.

When planning an electronics project, PCB quotes play a critical role. They provide vital information on costs, which influences the overall budget. Without accurate quotes, project leaders might face unexpected expenses later. It’s not uncommon to overlook hidden costs. Small variations in specifications can lead to significant budget shifts.

Moreover, PCB quotes help set realistic project timelines. Delays often stem from underestimating the time required for board production. A detailed quote can pinpoint lead times for fabrication and assembly. This foresight helps teams plan better. However, it’s easy to get lost in technical jargon when reviewing quotes. It can lead to miscommunications and mistakes. Each project demands clarity and precision from the start.

Delving deeper into quotes can expose areas for improvement in design. For instance, a quote might highlight costly components that could be substituted with more affordable options. It’s a chance to evaluate choices. Many projects overlook this, missing valuable insights. Taking the time to analyze quotes is often neglected. Yet, it can be transformative for budgets and timelines.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |