When it comes to designing and manufacturing printed circuit boards (PCBs), understanding the nuances of PCB fabrication in the USA is crucial for achieving high-quality results. In an industry driven by rapid technological advancements and stringent performance requirements, ensuring that you have the right information at your fingertips is paramount. This article outlines ten essential tips that can significantly enhance your PCB fabrication process, helping you to navigate through the complexities of sourcing, design, and production in the USA.

As the demand for sophisticated electronic devices continues to grow, the need for precise and reliable PCB fabrication cannot be overstated. The USA boasts a robust infrastructure for electronic manufacturing, with a range of suppliers and manufacturers who offer cutting-edge services. However, for both newcomers and seasoned professionals, familiarizing oneself with the best practices in PCB fabrication is key to optimizing quality and cost-effectiveness. The following tips not only cover technical aspects but also explore available resources and strategies to streamline your PCB projects. By leveraging these insights, you will be better equipped to tackle any challenges that arise in the PCB fabrication process and ensure the success of your electronic designs.

PCB fabrication is a crucial process in electronic manufacturing, involving several key steps to ensure quality and functionality. Initially, design specifications are translated into a physical layout, often using specialized software that allows engineers to visualize the circuit’s structure. This schematic must consider factors such as trace width, spacing, and component placement to optimize the performance of the final product.

Once the design is finalized, the fabrication process typically includes layering, etching, and drilling. These steps begin with applying a copper layer onto a substrate, followed by photolithography to imprint the circuit pattern. After etching to remove unwanted copper, holes are drilled for component placement. Each procedure plays a vital role in creating reliable and efficient PCBs. Understanding these fundamental steps is essential for manufacturers aiming to produce high-quality PCBs that meet industry standards and customer expectations.

| Tip Number | Tip Description | Importance Level | Expected Outcome |

|---|---|---|---|

| 1 | Understand the PCB Design Software | High | Improved Design Accuracy |

| 2 | Choose the Right Material | Medium | Enhanced Reliability |

| 3 | Set Realistic Tolerances | High | Reduced Manufacturing Issues |

| 4 | Optimize Layer Count | Medium | Cost Efficiency |

| 5 | Ensure Proper Component Placement | High | Improved Assembly Efficiency |

| 6 | Test Early and Often | High | Identify Issues Quickly |

| 7 | Communicate with Your Manufacturer | Medium | Smoother Production Process |

| 8 | Investigate Finishing Options | Medium | Quality Improvements |

| 9 | Consider Environmental Regulations | Medium | Compliance and Sustainability |

| 10 | Stay Educated on Industry Trends | Medium | Better Prepared for Future Challenges |

In the rapidly evolving world of PCB manufacturing, understanding the key materials and components is essential for success. The shift towards advanced materials is a response to the increasing demands for performance, efficiency, and reliability in electronic devices. Copper-clad laminates (CCLs) and high-frequency materials have gained prominence as they provide the necessary conductivity and thermal management for modern applications, particularly in automotive and AI server technologies.

Furthermore, the integration of more complex designs, such as multi-chip assemblies, showcases the industry's move towards miniaturization and functionality enhancement. This trend not only improves performance but also helps reduce power consumption, which is becoming a critical factor as the market anticipates the growth of the automotive PCB sector from $9.15 billion in 2023 to $15.1 billion by 2032. The evolution of these components in PCB fabrication represents a significant advancement that aligns with the industry's shift towards smarter, more compact devices.

In the ever-evolving landscape of PCB fabrication in the USA, understanding regulatory compliance and industry standards is crucial for manufacturers. The recent focus on sustainability has transformed the PCB manufacturing sector, as companies anticipate increasing efforts towards eco-friendly practices by 2025. This shift emphasizes not only compliance with regulations but also a commitment to environmental responsibility, pushing manufacturers to explore sustainable materials and processes.

Additionally, guidance from regulatory bodies such as the FDA underscores the importance of supply chain security and remote regulatory assessments. These measures are designed to ensure that manufacturing processes adhere to safety standards and contribute positively to the overall quality of electronic components. As manufacturers navigate these regulatory landscapes, staying informed about the latest trends and compliance requirements will be essential for maintaining a competitive edge in the market.

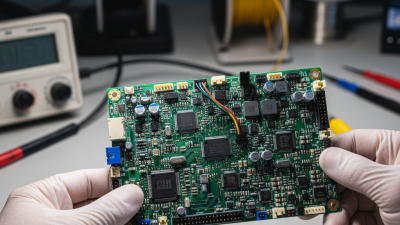

In the world of PCB fabrication, companies often grapple with several common challenges that can impede production efficiency and product quality. One significant challenge is the choice of plating solutions, such as copper, nickel, gold, silver, and tin. Each solution presents specific advantages and drawbacks in terms of conductivity, solderability, and cost. For instance, gold plating is favored for its excellent conductivity but can be expensive, while copper is more cost-effective yet may not provide the same level of protection against corrosion.

Another critical aspect is ensuring proper application techniques, such as those for through-hole plating and surface mount technologies. Inadequate execution can lead to defects, compromising the reliability of the finished product. To mitigate these challenges, manufacturers are adopting advanced technologies and quality assurance processes, including automated inspection techniques like ICT, to enhance accuracy in component placement and solder integrity. This focus on overcoming production hurdles is essential for maintaining market competitiveness and addressing the growing demand in sectors like automotive electronics. As the market for PCBs continues to evolve, understanding these challenges and their solutions remains vital for successful fabrication.

When it comes to PCB fabrication, implementing best practices for quality control is paramount. Effective quality control not only ensures the functional reliability of the final product but also enhances manufacturing efficiency and reduces costs. One essential tip is to establish a comprehensive inspection protocol at every stage of the fabrication process. This includes raw material verification, in-process inspections, and final product assessments. Utilizing state-of-the-art testing technologies, such as automated optical inspection (AOI) and X-ray inspection, can significantly increase the chances of identifying defects early and mitigating potential issues.

Additionally, fostering a culture of continuous improvement among the workforce is crucial. Training employees to recognize quality standards and empower them to suggest improvements can lead to enhanced operational excellence. Emphasizing collaboration between design and manufacturing teams helps to streamline processes and tackle issues proactively. By prioritizing these quality control practices, PCB manufacturers can not only meet stringent industry standards but also position themselves favorably in the competitive landscape.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |