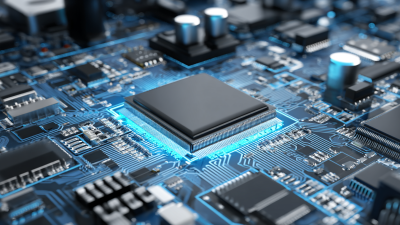

Choosing the right PCB manufacturer in the USA is crucial for your project. The quality of the printed circuit board (PCB) can impact the performance of your electronic devices. When searching for a PCB USA manufacturer, consider their experience, certifications, and technology.

Many manufacturers claim to provide the best service. However, not all meet industry standards. You may find inconsistent quality in some cases. It's essential to invest time in research. Look at reviews, past projects, and client testimonials to gauge their reliability.

Cost is another factor to evaluate. Some companies offer low prices but compromise on quality. Balancing cost and quality is vital. Make sure your chosen PCB manufacturer aligns with your project goals. Taking these steps can lead to a successful partnership.

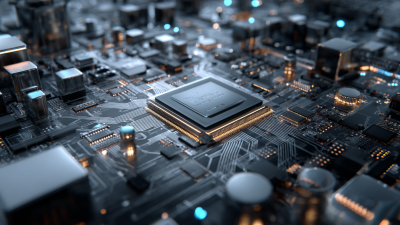

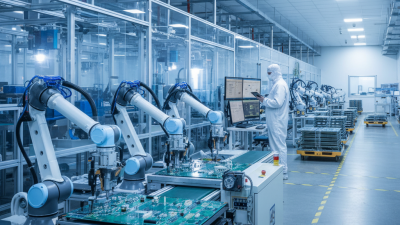

When selecting PCB manufacturers in the USA, understanding key factors is essential. The complexity of PCB design requires careful evaluation of capabilities. The average turnaround time for PCB manufacturing is about four weeks, but many companies offer expedited options. Consider whether a manufacturer can meet your deadlines without compromising quality.

Price is another critical factor. According to a recent industry report, costs can vary dramatically based on materials and specifications. It's common to see prices range from $5 to $30 per square inch. Low-cost options might seem appealing, but they may lack the quality standards. Thin layers and fine pitch require a more skilled manufacturer.

Quality assurance processes are vital. Look for manufacturers who follow strict ISO standards. A quarter of all PCBs manufactured experience some form of defect. This highlights the importance of choosing a reliable partner. Manufacturers should conduct regular inspections and provide detailed reports. Not all factories are equipped for advanced technologies like HDI or multilayer boards. Ask about their capabilities. Assessing these factors ensures you choose a manufacturer that meets your project needs effectively.

When evaluating PCB manufacturers in the USA, it's crucial to assess their technical capabilities. Look for companies that offer diverse manufacturing processes. Techniques like surface mount technology and through-hole technology can indicate a manufacturer’s flexibility. Additionally, consider their production volume capabilities. Some may specialize in small batches, while others handle high volume orders efficiently.

Quality assurance processes are another important area to scrutinize. Manufacturers should have robust testing protocols. These may include automated optical inspection or functional testing. However, not all providers adhere to strict standards, leading to inconsistencies in product quality. It’s wise to request case studies or examples of their work. This gives insight into their problem-solving skills and engineering competence.

Communication is vital throughout the manufacturing process. Delays or misunderstandings can hinder project timelines. A responsive team can alleviate concerns promptly. Yet, some manufacturers may lack effective communication strategies. This can lead to misalignment between expectations and delivery. Relying solely on online reviews may also be misleading, as experiences can vary widely.

| Criteria | Rating (1-5) | Comments |

|---|---|---|

| Manufacturing Experience | 5 | Over 20 years in the industry, expertise in complex PCB designs. |

| Quality Assurance | 4 | Certifications in ISO 9001 and IPC standards. |

| Technology Used | 5 | Utilizes state-of-the-art machinery and CAD software. |

| Lead Time | 3 | Standard turnaround time of 2-4 weeks. |

| Customer Support | 5 | Dedicated account managers and 24/7 support available. |

| Cost Competitiveness | 4 | Prices are reasonable but slightly higher for premium services. |

When selecting PCB manufacturers in the USA, assessing quality standards is crucial. Different certifications signal a reliable manufacturer. Look for IPC standards, which focus on printed circuit board quality. An ISO 9001 certification indicates strong management practices. These standards ensure consistency and reliability in production.

Tips: Always check if the manufacturer is up to date with certifications. Outdated qualifications can signal a lack of attention to quality. Don't hesitate to ask for copies of their certifications; transparency is key in this industry.

Additionally, review customer feedback and case studies. Quality is not just about certifications; it also reflects customer experiences. Some manufacturers may excel on paper but fall short in practice. Seek out those with a strong reputation for quality and responsiveness. Remember, a good manufacturer listens to feedback and evolves accordingly.

When choosing a PCB manufacturer in the USA, cost and quality are crucial considerations. Many companies offer low prices, but this may lead to subpar products. The risk of defects increases with cheaper options. For example, a poorly manufactured PCB could cause device malfunctions. This situation can lead to expensive recalls or repairs.

Balancing cost and quality is essential for manufacturing. Higher quality materials often mean better performance and longevity. In contrast, investing in low-cost PCBs might save money initially but could result in more expenses down the line. It’s worth asking potential manufacturers about their quality control processes. A transparent approach to manufacturing often indicates a commitment to quality.

Many manufacturers provide detailed specifications. You should look for certifications that demonstrate adherence to industry standards. However, not all certifications guarantee excellence. Researching customer reviews can reveal insights about actual performance and reliability. It’s important to weigh these factors carefully to avoid costly mistakes.

When researching PCB suppliers, customer reviews offer invaluable insights. Reading what other clients say about their experiences can guide your decision. Look for reviews that detail quality, delivery timelines, and customer support. A mix of positive and negative feedback often reveals the true nature of a manufacturer. It's important to discern genuine reviews from those that appear overly promotional.

Case studies can also inform your choice. They illustrate how a manufacturer has solved specific problems. Examine the contexts presented in these case studies. Not every company will resonate with your needs. Some may lack scalability for larger projects, while others may not meet stringent quality requirements. Analyze these details carefully.

Consider reaching out to manufacturers for references too. Speak directly with previous clients if possible. This direct line of communication can uncover vital details that reviews might miss. Every insight will help you weigh your options and anticipate potential challenges. Be critical in your assessment; ensure you make a well-informed choice for your PCB needs.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |