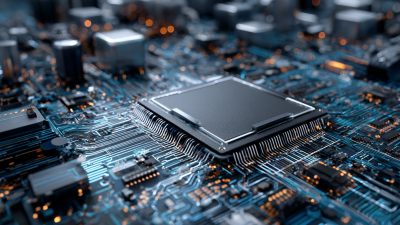

In the rapidly evolving landscape of electronics, the importance of efficient PCB design cannot be overstated. According to a recent report by Market Research Future, the global PCB market is projected to grow at a compound annual growth rate (CAGR) of 4.3% between 2021 and 2026. This growth underscores the increasing demand for high-quality circuit boards in various applications, from consumer electronics to automotive systems. As beginners venture into this intricate field, understanding the foundational principles of PCB design is crucial for developing effective and reliable circuit boards.

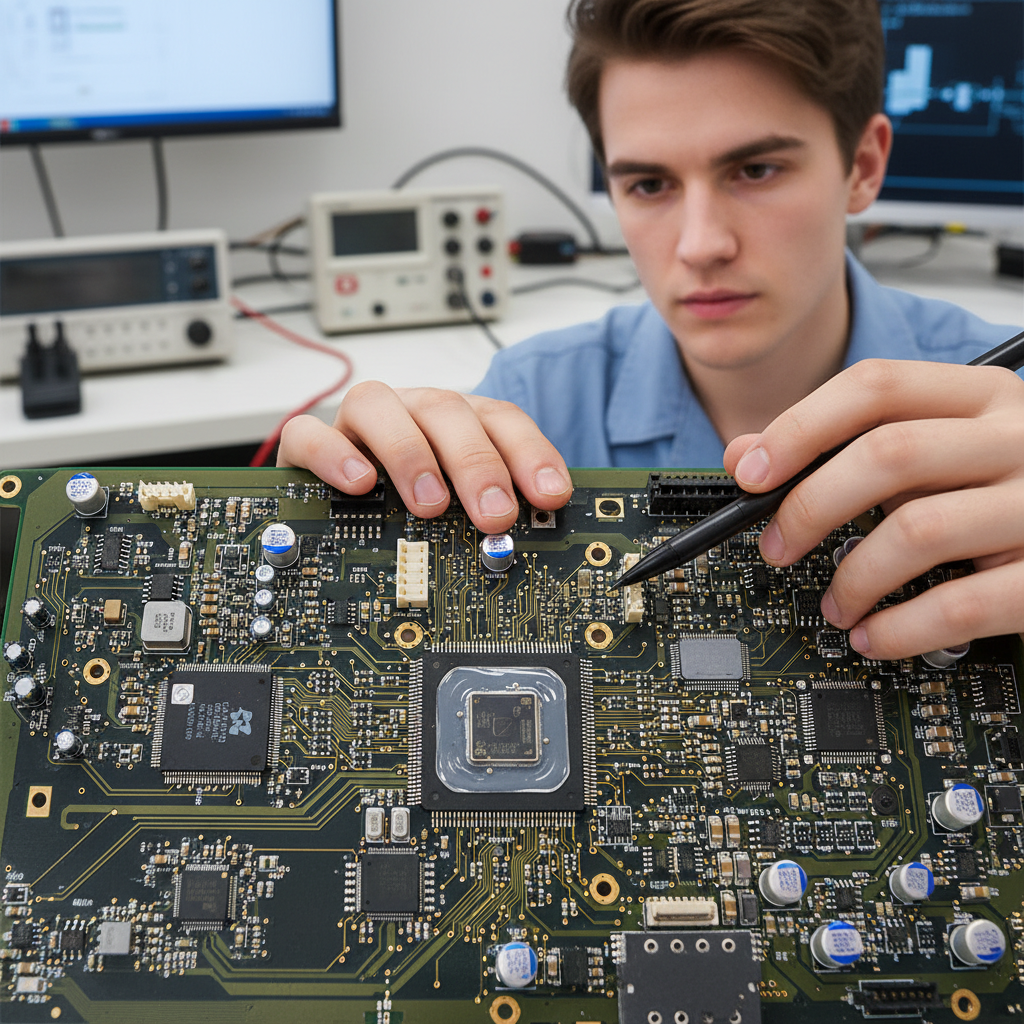

Experts in the field emphasize the significance of proper PCB design techniques. Dr. Emily Chen, a recognized authority in electronic engineering and PCB technology, states, "A solid understanding of PCB design fundamentals can significantly enhance product performance and manufacturability." For newcomers, mastering the essentials of PCB design is not merely an academic exercise; it is a vital step toward ensuring that their products stand out in the competitive market. This article presents the top 10 PCB design tips aimed at guiding beginners through the complexities of crafting efficient and functional circuit boards, ultimately contributing to their success in this dynamic industry.

The process of PCB design involves several crucial steps that ensure a successful outcome. From

initial concept to prototype, each phase requires careful attention to detail and optimization. Recently, advancements in

AI-driven tools have revolutionized PCB layout optimization, allowing engineers to work within

their preferred design environments and streamline their workflows. According to industry reports, integrating AI in PCB design can

significantly reduce production time by up to 30%, enabling faster iterations and improvements in

circuit board performance.

When embarking on PCB design, consider these essential tips: Firstly, always start with a clear schematic, as it serves as the backbone of the design.

Secondly, select the right PCB design software tailored to your project needs—recent evaluations identified the top tools that enhance productivity and functionality.

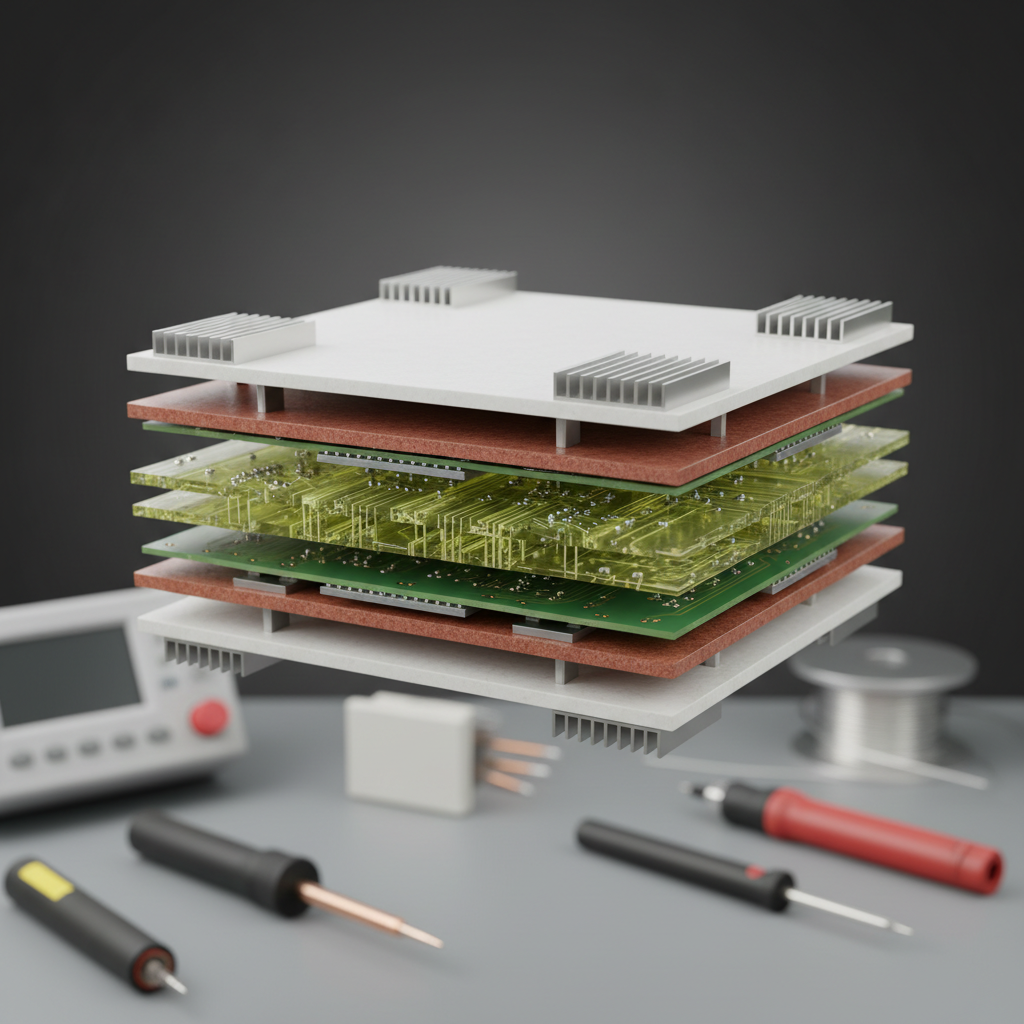

Lastly, incorporate 3D modeling early in the design process; studies indicate that using 3D representations can reduce error rates by as much as 50%, leading to

more efficient designs and better utilization of space. Embrace these strategies to navigate the complexities of PCB design and create

effective circuit boards.

When embarking on PCB design, choosing the right substrate is crucial for ensuring optimal performance. The substrate serves as the foundation for the circuit board, influencing electrical performance, thermal management, and overall durability. Common materials like FR4, which combines fiberglass with epoxy resin, are popular for their balance of cost and functionality. However, for high-frequency applications, materials like Rogers or ceramic might be more suitable due to their lower dielectric loss and better thermal conductivity.

Another key factor to consider is the thickness of the substrate. Thinner materials can reduce weight and improve flexibility, making them ideal for compact electronic devices. Conversely, thicker substrates may provide enhanced structural integrity and support for components. Additionally, understanding the specific requirements of your project, such as operating temperature, environmental conditions, and potential mechanical stress, will guide you in selecting the most appropriate substrate.

By thoughtfully considering these elements, beginners can create efficient and reliable circuit boards tailored to their project's needs.

Design rules are essential for creating error-free printed circuit boards (PCBs), especially for beginners who may not fully grasp the nuances of PCB design. Research from IPC, an industry association for electronics manufacturing, indicates that nearly 70% of PCB design errors are attributed to violations of design rules. Adhering to these guidelines not only minimizes the risk of faults but also enhances the reliability and performance of the final product.

Incorporating specific design rules such as trace width, spacing, and layer stack-up can significantly impact the manufacturability and electrical performance of a PCB. For instance, ensuring that traces are sufficiently wide can prevent overheating and ensure reliable current flow, while correct spacing can mitigate the risk of dielectric breakdown. According to a report by the European Institute of Innovation and Technology, the application of rigorous design rules can reduce development costs by up to 30%, emphasizing their critical role in efficient circuit board design. By prioritizing these guidelines, beginners can set a strong foundation for successful PCB design while avoiding common pitfalls that can arise from oversight.

| Tip Number | Design Tip | Importance | Resources |

|---|---|---|---|

| 1 | Understand Design Rules | Prevents errors and rework | Datasheets, PCB design guidelines |

| 2 | Choose the Right Components | Ensures compatibility and reliability | Component libraries, supplier websites |

| 3 | Optimize PCB Layout | Improves signal integrity and performance | Layout tools, simulation software |

| 4 | Maintain Proper Spacing | Reduces the risk of shorts | Design rule check features |

| 5 | Use Ground Planes | Reduces electromagnetic interference | PCB design software tutorials |

| 6 | Plan for Thermal Management | Prevents overheating | Thermal analysis tools, design guides |

| 7 | Review Schematic Carefully | Catches logic errors early | Schematic capture software |

| 8 | Verify Design with DRC | Ensures compliance with design rules | Design rule check tools |

| 9 | Plan for Testing | Facilitates quicker troubleshooting | Test point guidelines |

| 10 | Document Design Changes | Maintains design integrity | Version control systems |

In the realm of PCB design, the utilization of simulation software has become a game-changer for beginners aiming to create efficient circuit boards. According to a report by PCB Design Magazine, nearly 80% of designers now incorporate simulation tools into their workflow, significantly reducing prototyping costs and time. These tools allow engineers to visualize how their designs will perform under various conditions, making it easier to identify and rectify potential issues before physical prototypes are ever made.

One key benefit of employing simulation software is the ability to analyze electrical characteristics, thermal behavior, and mechanical stresses virtually. This practice greatly enhances design reliability; a survey from the IPC (Institute for Printed Circuits) revealed that projects using simulation software experience a 30% decrease in rework, which leads to faster time-to-market and better resource management. As circuit boards become increasingly complex, harnessing the power of simulation not only fosters innovation but also equips beginners with the confidence needed to experiment and improve their designs efficiently.

To optimize PCB production costs without sacrificing quality, implementing strategic design tips can significantly impact your budget. A recent industry report predicts that the global PCB market will exceed $80 billion by 2025, highlighting the importance of efficiency in production. One fundamental tip is to minimize the number of layers in your PCB design. A single-layer PCB tends to cost less and is easier to produce, which can effectively lower manufacturing expenses. Keep in mind that this might limit complexity, so evaluate the design requirements carefully.

Additionally, choosing the right materials can lead to substantial savings. According to a survey conducted by IPC, about 45% of PCB manufacturers consider material costs as a primary factor in overall production expenses. Opting for standard materials instead of custom solutions can reduce costs. For example, using FR-4 material, the most common laminate, can result in significant savings while still maintaining acceptable performance levels. Finally, utilizing design software that allows for automated layout optimization can help identify potential manufacturing issues early, thus reducing the risk of costly design revisions later on. By focusing on these aspects, beginners can ensure their PCBs are both cost-effective and high quality.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |