PCB fabrication is a complex process fundamental to electronic device manufacturing. Experts in the industry highlight the importance of quality and precision. John Smith, a renowned PCB fabrication specialist, once stated, "The quality of a PCB determines the reliability of the entire device." This underlines how critical the fabrication process is in achieving high standards.

The PCB fabrication process involves multiple steps. It starts with design and proceeds to etching circuits onto a substrate. Each step must be executed with care, as errors can lead to costly failures. For many, the intricacies of this process can be daunting. Not all manufacturers achieve the desired quality, leading to variability in products.

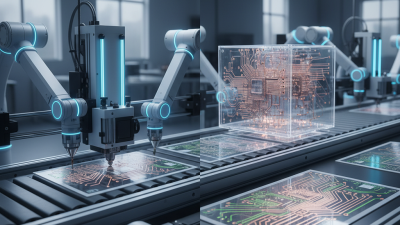

Additionally, technology is constantly evolving. New materials and techniques emerge regularly, challenging even the most experienced professionals. It's vital for the industry to adapt, yet sometimes it struggles to keep pace. Thus, understanding PCB fabrication continues to be a key area of focus for engineers and manufacturers alike.

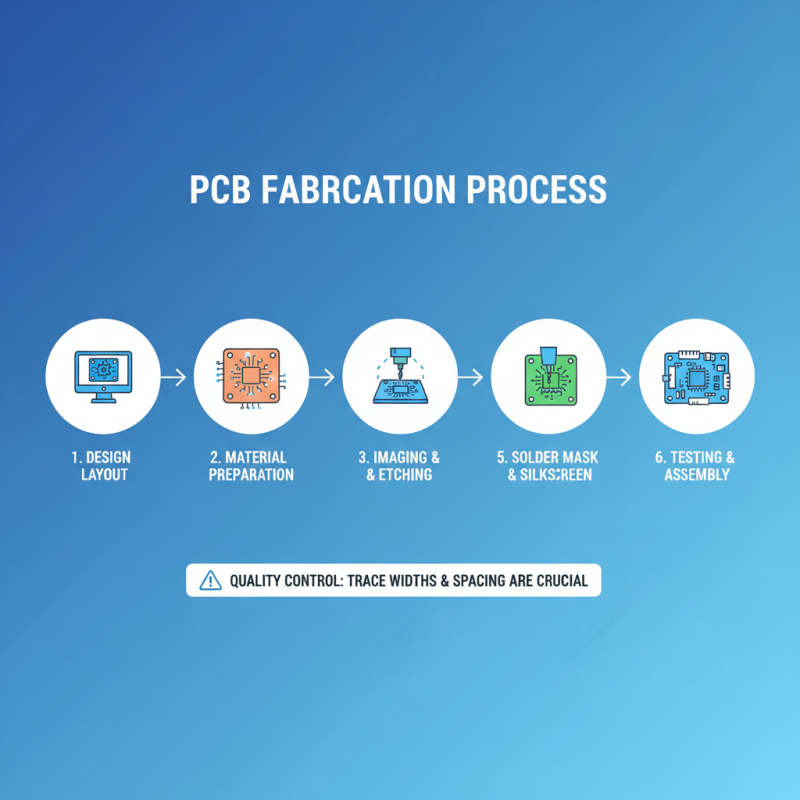

PCB fabrication is the process of creating printed circuit boards. These boards serve as the foundation for electronic components. The fabrication process involves several key stages including design, etching, and assembly.

Initially, a schematic is designed using specialized software. This design is then transformed into a layout that represents the physical board. After this, photoresist material is applied to a copper-clad substrate. This step is critical. If not done correctly, errors can occur, leading to board failure.

The board is then exposed to UV light, which hardens the photoresist. Unwanted copper is removed during the etching process. This reveals the intricate circuit patterns. Finally, components are attached through soldering. However, human error is always a risk here. A misplaced component can lead to short circuits. Therefore, precision is key to successful PCB fabrication.

PCB fabrication plays a crucial role in the electronics industry. It is the process that transforms electrical designs into functioning electronic circuits. A report by PCB Design & Fabrication shows that the global PCB market is projected to reach $85.3 billion by 2025. This growth reflects the rising demand for electronic devices across various sectors.

Effective PCB fabrication ensures reliability and performance in electronic devices. Quality control during the process is essential. According to a survey from Electronic Supply Chain, about 30% of PCBs experience issues due to fabrication errors. These problems can lead to device malfunctions. In some cases, this results in costly recalls or product failures. Hence, optimizing the fabrication process is more critical than ever.

Despite advancements, challenges remain. Many fabricators struggle with meeting tight deadlines while maintaining high quality. Innovations like automated inspection are helping, but not all manufacturers adopt these technologies. This reluctance can hinder progress. Addressing these issues is necessary for ensuring the longevity and efficiency of electronic products.

The PCB fabrication process involves several key steps. It starts with designing the circuit layout, commonly done using specialized software. Designers must ensure trace widths and spacing meet electrical requirements. It's tricky sometimes; mistakes can lead to shorts or performance issues.

Next comes photolithography. A photoresist layer is applied to the copper-clad board. Exposing it to ultraviolet light through a mask transfers the circuit pattern. This part is delicate—setting the right exposure time is essential. Any miscalculation can cause loss of detail or incomplete patterns.

After that, etching removes unwanted copper, leaving behind only the desired circuitry. Various chemicals are used, and accuracy is crucial at this stage. Over-etching can ruin a board. Once cleaned, the board undergoes drilling and plating before final inspection. Here, imperfections might slip through, necessitating a thorough review. Each step requires precision and attention to detail for successful PCB fabrication.

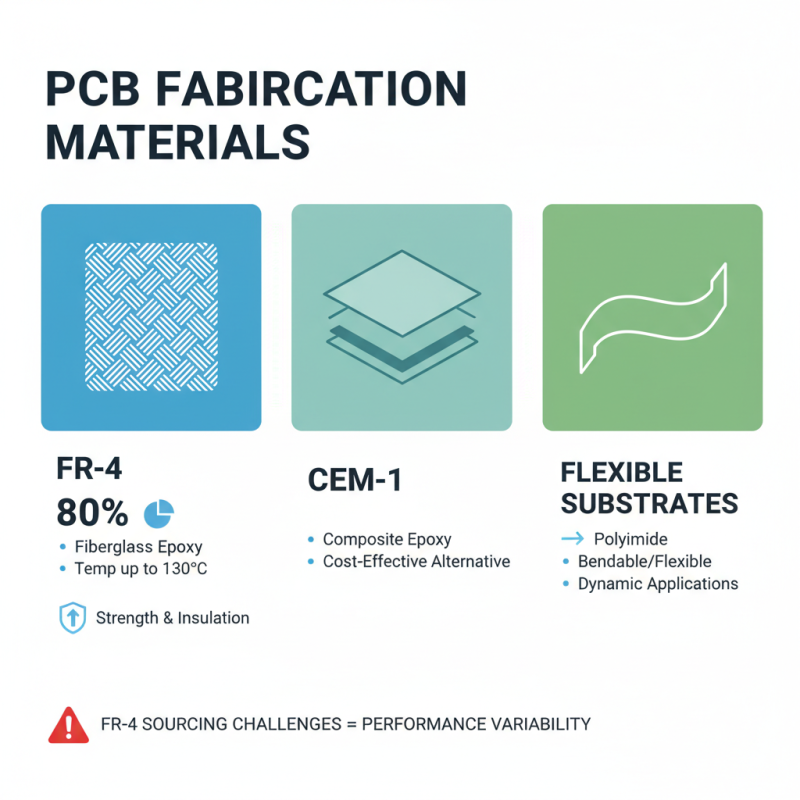

PCB fabrication relies heavily on the choice of materials. The most common materials used are FR-4, CEM-1, and flexible substrates like polyimide. According to industry reports, FR-4, a fiberglass epoxy laminate, constitutes about 80% of PCB materials due to its excellent insulating properties and mechanical strength. It withstands temperatures up to 130°C, making it suitable for a variety of electronic applications. However, sourcing quality FR-4 can be challenging, leading to variability in performance.

CEM-1 is another prevalent option. It consists of a paper base, offering a lower cost alternative to FR-4. Reports show that CEM-1 is favored for single-layer PCBs. However, its durability and thermal resistance are not as impressive. This might raise concerns for projects requiring long-term reliability.

Flexible substrates like polyimide are crucial for applications needing bendable circuit designs. They provide good thermal stability and are lightweight. Nevertheless, flexibility can sometimes translate to fragility. Choosing the right material is vital for the project’s success. Designers often face a dilemma: cost versus performance. Balancing these aspects can be tough. Understanding the physical properties of each material is essential but often overlooked.

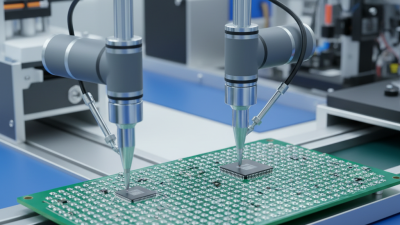

Quality control is crucial in PCB fabrication. Every step must be carefully monitored. The process involves designing, layering, and etching. Each layer needs scrutiny. Minor flaws can lead to major failures. This makes testing indispensable.

One approach is visual inspection. Workers check for defects by eye. This is time-consuming and not foolproof. Many companies use automated optical inspection. It can catch errors more efficiently. However, machines may overlook subtle issues.

Functional testing follows the fabrication. It ensures that the PCB works as intended. Sometimes, boards pass visual checks but fail functionality. This can result in costly delays.

Regular audits and updates to testing protocols help. Yet, there is always room for improvement. Balancing speed and accuracy is a constant challenge.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |