PCBA manufacturing plays a crucial role in the electronics industry. It involves assembling printed circuit boards (PCBs) with electronic components. This process greatly influences the design and production of electronic devices.

Many businesses rely on PCBA manufacturing for high-quality products. However, the industry's complexities often lead to mistakes. Poor quality control can result in defects or failures. Manufacturers must address these issues to improve efficiency and reliability.

In today's fast-paced market, innovation is vital. Companies that ignore the importance of PCBA manufacturing risk falling behind. They may create products that do not meet consumer expectations. Therefore, investing in quality PCBA manufacturing is essential for success.

PCBA manufacturing, or printed circuit board assembly, plays a vital role in electronics production. This process involves mounting electronic components onto a circuit board. It transforms raw materials into functional electronics. Without PCBA, many products, from smartphones to home appliances, would not exist.

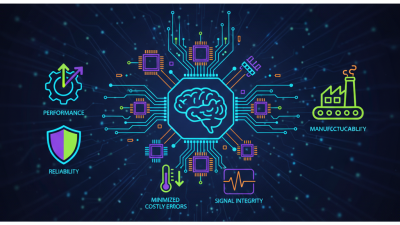

In the heart of PCBA manufacturing is the intricate balance of precision and quality. Each component must fit perfectly on the board. Errors can lead to costly failures. Many manufacturers face challenges with soldering defects or misplaced components. These issues highlight the need for constant improvement and vigilance in manufacturing processes.

Moreover, the role of PCBA extends beyond assembly. It influences design decisions and material selection. The trend toward miniaturization makes this even more critical. Designers must carefully consider space and component placement. While technology evolves rapidly, some basic challenges persist. Ensuring reliability and performance remains a priority. Despite advancements, the industry still seeks solutions to enhance efficiency and minimize waste.

PCBA manufacturing involves several critical processes that shape the electronics industry. Initially, designers create a schematic. This schematic then transitions to a printed circuit board (PCB) layout. The layout must be precise. Any small error can lead to significant issues later on. Layouts are usually verified through simulation software. This step helps to catch mistakes early.

After finalizing the layout, the manufacturing process begins. Components are sourced and prepared. Surface mount technology (SMT) is commonly used. In this process, components are soldered directly onto the PCB. This method allows for high-density designs but can also lead to misalignment. Such misalignment might impact performance. Wave soldering is another technique used to join components, especially for through-hole parts. Each method has unique advantages and challenges.

Finally, testing is a crucial phase. The board needs to be evaluated for functionality. Automated test equipment (ATE) can identify defects efficiently. But, reliance on automation can sometimes overlook subtle issues that require human inspection. As technology evolves, the processes will also need to adapt. Continuous improvement is essential for maintaining quality in PCBA manufacturing. The evolving nature of this field often leads to learning opportunities and reflections on past practices.

Quality control is essential in PCBA manufacturing. It ensures that every circuit board meets required specifications before it reaches the hands of the customer. The process involves multiple checks, from the initial design phase to final assembly. Components must be tested for functionality and reliability. Any defects can lead to system failures.

One common quality control measure is automated optical inspection. This method can spot surface defects early. However, it does not catch all errors. Some issues are only visible during the functional testing phase. Even skilled technicians can miss subtle discrepancies. Regular audits and ongoing training for staff are crucial. These efforts help maintain high standards.

Another important aspect is traceability. Each component must be tracked through the manufacturing process. Missing records can complicate defect identification. It’s vital to establish clear documentation protocols. Transparency in processes leads to better accountability. While numerous measures exist, the industry must remain vigilant. Continuous improvement in quality control should always be a priority.

| Quality Control Measure | Description | Impact on PCBA |

|---|---|---|

| Incoming Material Inspection | Verification of raw materials to ensure they meet specifications. | Reduces defects in the final product. |

| In-Process Quality Control | Monitoring production processes to detect issues early. | Minimizes waste and ensures conformity. |

| Functional Testing | Testing assembled boards for operational functionality. | Ensures reliability and performance of PCs. |

| Environmental Testing | Assessing performance under extreme conditions. | Guarantees durability in various applications. |

| Final Inspection | Comprehensive review before shipment. | Prevents defective products from reaching customers. |

PCBA manufacturing plays a crucial role in the electronics industry. It combines electronic components on a printed circuit board. This process directly affects both cost and efficiency for manufacturers. Every step, from component placement to soldering, requires precision. Minor errors can lead to significant waste and higher production costs. Inaccuracies can arise, impacting quality. Factories must constantly improve to remain competitive.

The efficiency of PCBA manufacturing influences time to market. A shorter production cycle enables companies to launch products quickly. Yet, high-tech components can drive costs up. Balancing cost and quality is essential. Some manufacturers opt for cheaper materials, which can compromise performance. This decision can lead to future recalls or failures, causing greater financial loss. Suppliers should consider the long-term impacts of their choices.

Manufacturers also need to assess their processes regularly. Aging equipment might slow production. New technologies are available that can optimize workflows. Investing in training for employees is vital. Skilled workers contribute to a more efficient process. Ultimately, the decisions made in PCBA manufacturing ripple through the entire electronics landscape. Attention to detail can yield substantial benefits, but overlooking aspects can create pitfalls.

This chart illustrates the impact of PCBA manufacturing on cost and efficiency in the electronics industry. The cost of manufacturing PCBA is shown at $1500, while the efficiency achieved through this process is represented at 85%. This highlights the significant role that PCBA plays in optimizing both financial and operational aspects of electronics production.

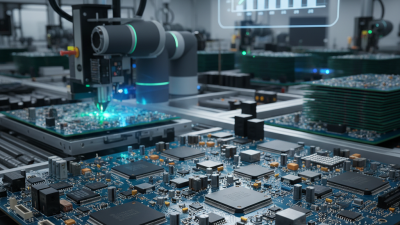

The landscape of PCBA (Printed Circuit Board Assembly) manufacturing is evolving rapidly. Emerging technologies are changing how PCBAs are produced.

Automation is a key trend, with robots performing tasks faster and reducing human error. However, automation raises concerns about workforce displacement and the need for skilled labor in oversight.

Another significant trend is the shift towards sustainable practices. Manufacturers are exploring eco-friendly materials and processes. While this approach can reduce waste, it poses challenges. Finding suitable sustainable materials that meet performance standards is not always easy. Moreover, the transition can require substantial investment, which not all companies can afford.

Lastly, the move towards IoT (Internet of Things) integration in electronics is impactful. As devices become smarter, PCBA designs must adapt. This complexity can lead to longer product development cycles. It may also strain manufacturers who are unprepared for such changes. Balancing innovation and practicality remains a pressing concern for the industry.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |