In today's fast-paced technological landscape, the demand for efficient and cost-effective solutions in printed circuit board (PCB) manufacturing has never been higher. Whether you're a seasoned engineer or a hobbyist, understanding how to navigate the online PCB order process can significantly impact both the speed and affordability of your projects. This guide aims to demystify the steps involved in placing a PCB order online, ensuring that you have all the necessary tools and knowledge at your fingertips.

The convenience of online PCB ordering platforms has opened up opportunities for designers to quickly transform their ideas into tangible products. By following a streamlined process, you can reduce lead times and manage costs effectively. From selecting the right specifications to uploading your design files, each step plays a crucial role in achieving the desired outcome. With this introduction, you'll be equipped to make informed decisions that align with your project needs, ultimately leading to successful PCB manufacturing experiences.

Understanding the PCB manufacturing process is crucial for anyone looking to place an order online. The journey typically begins with design verification, where engineers ensure that the printed circuit board (PCB) design meets all necessary specifications. This involves checking the layout against manufacturing constraints, verifying component placements, and ensuring proper trace widths and spacings to avoid potential issues during production. Once the design is validated, it moves into the manufacturing phase, which can vary depending on the chosen technology and materials.

There are several options available in PCB manufacturing, including selecting the specific type of substrate, copper thickness, and surface finishes. Common materials used for PCBs include FR-4 fiberglass and polyimide for flexible circuits. The manufacturing processes may also differ; traditional methods like subtractive and additive manufacturing can produce complex designs efficiently. Moreover, advancements in technology have introduced rapid prototyping options, allowing for quicker turnaround times without compromising quality. By understanding these processes and options, customers can make informed decisions that align with their project requirements and budget constraints.

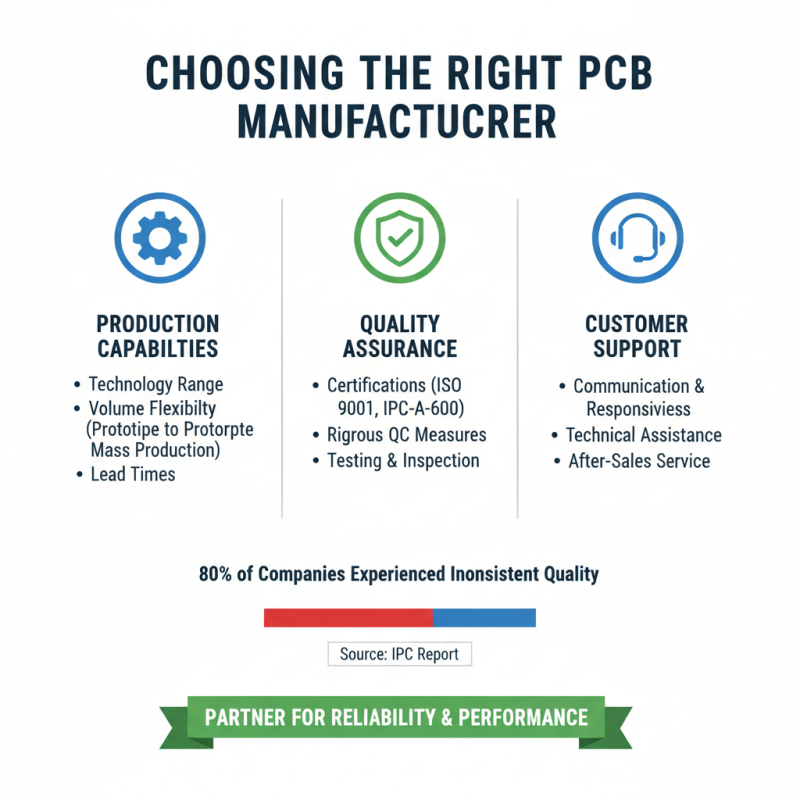

When choosing the right PCB manufacturer, it is essential to consider factors such as production capabilities, quality assurance, and customer support. According to a report by IPC, a leading trade association for the electronics manufacturing industry, more than 80% of companies have experienced issues with inconsistent quality when working with PCB suppliers. This statistic underscores the importance of partnering with a manufacturer that employs rigorous quality control measures and can provide certifications like ISO 9001 and IPC-A-600.

Another critical aspect to evaluate is manufacturing speed. Many PCB manufacturers can offer expedited services, with the ability to produce prototypes in as little as 24 hours. As per the latest industry trends, over 70% of companies prioritize quick turnaround times for their projects. Make sure to inquire about the manufacturer's production lead times and their ability to scale production based on your needs.

**Tips:** Before making a decision, request samples of their previous work to assess the quality. Additionally, check reviews and testimonials from other clients to gauge their reliability. Engaging in direct communication with the manufacturer can also help you understand their processes and responsiveness, which is vital for a smooth development experience.

Preparing your PCB design files for submission is a crucial step in ensuring a smooth and efficient manufacturing process. First, it's essential to verify that your design files are complete and adhere to established design rule checks. Ensure that all components are properly placed, and traces are adequately sized to handle the expected electrical load. Using industry-standard file formats, such as Gerber and ODB++, will also facilitate a smoother transition from design to production. It’s advisable to include all necessary layers, such as copper, solder mask, silkscreen, and drill files, to provide a comprehensive view of your design.

Next, pay attention to the documentation that accompanies your design files. Including a Bill of Materials (BOM) is critical, as it lists all components used in the PCB and their specifications, enabling manufacturers to understand requirements at a glance. Additionally, providing assembly instructions, if applicable, can significantly reduce errors during manufacturing. Clear annotations within your design files can also assist manufacturers in recognizing critical areas of your PCB, such as power connections or sensitive components that require special handling. By meticulously preparing your design files and documentation, you can help ensure that your PCB order is processed quickly and meets your specifications without unexpected delays.

Ordering a printed circuit board (PCB) online has become increasingly streamlined, making it easier for engineers and hobbyists alike to get their projects off the ground. The first step in the online ordering process typically involves choosing a reliable PCB manufacturer. This can be done by researching potential suppliers online, checking their reviews, and comparing their service offerings. Once a suitable manufacturer is selected, you need to prepare your PCB design files, which are usually generated using specialized software. It's essential to ensure your files meet the manufacturer’s design rules to avoid delays or issues during production.

After your design files are ready, you will upload them through the manufacturer's website, where you'll be prompted to select various options such as board thickness, layer count, and surface finish. Pricing can often vary based on these selections, so be sure to review the available options carefully to find a balance between quality and affordability. Once you've confirmed your specifications, you will proceed to the payment phase. This step usually involves entering your shipping and billing information. Many manufacturers also provide tracking options, allowing you to stay updated on the status of your order. With a few clicks, your PCB order can be placed quickly and efficiently, ensuring a fast turnaround for your electronic projects.

When ordering printed circuit boards (PCBs) online, achieving a fast turnaround while maintaining cost efficiency is crucial for engineers and designers alike. According to a recent report by IPC, the global electronics manufacturing market is expected to exceed $1 trillion by 2025, emphasizing the importance of streamlined PCB production to keep pace with industry demands. One of the primary tips for ensuring a quick turnaround is to provide accurate and comprehensive design files. Missing or incorrect specifications in the design files can lead to delays and unexpected costs related to revisions. Utilizing standardized design formats like Gerber files can significantly reduce the time spent on clarifications.

Moreover, choosing manufacturers that employ automated processes can drastically lower costs while optimizing production speed. A study published by the Institute of Electrical and Electronics Engineers (IEEE) noted that manufacturers who integrate automated optical inspection (AOI) alongside pick-and-place machines can enhance productivity by up to 30%. This automation not only speeds up the assembly process but also minimizes human error, contributing to overall design integrity. Additionally, splitting larger orders into smaller batches can prove advantageous in managing lead times and inventory, allowing for quicker delivery of prototypes or smaller runs that meet the immediate needs of projects without compromising on quality or budget.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |