As we look toward 2025, the landscape of the printed circuit board (PCB) industry is set to undergo significant transformations. Experts predict that new technologies and shifts in consumer demands will shape the future of PCBs, influencing everything from design methods to materials used. Dr. Emily Chen, a leading figure in PCB innovation, emphasizes this shift by stating, "The evolution of printed circuit boards is not just about miniaturization; it's about integrating intelligent technologies that enhance functionality in versatile applications."

In this rapidly changing environment, staying informed on the latest trends becomes crucial for manufacturers and consumers alike. Key developments such as the increased adoption of flex and rigid-flex PCBs, along with advancements in sustainability practices, will likely dominate the conversation. Furthermore, the growing emphasis on high-density interconnect (HDI) technology signals a move towards more compact and efficient solutions.

In this rapidly changing environment, staying informed on the latest trends becomes crucial for manufacturers and consumers alike. Key developments such as the increased adoption of flex and rigid-flex PCBs, along with advancements in sustainability practices, will likely dominate the conversation. Furthermore, the growing emphasis on high-density interconnect (HDI) technology signals a move towards more compact and efficient solutions.

As we delve deeper into these trends, understanding their implications and opportunities will be vital for anyone involved in the printed circuit board sector. The journey to 2025 is not merely about keeping pace; it's about strategically positioning oneself to harness these innovations for future success.

As the demand for environmentally responsible manufacturing practices rises, the printed circuit board (PCB) industry is witnessing a significant shift towards eco-friendly methods. The global green electronics manufacturing market is poised for remarkable growth, projected to increase from $19 billion in 2024 to approximately $187 billion by 2034, showcasing a substantial compound annual growth rate (CAGR) of 26%. This surge is driven by heightened consumer awareness and regulatory pressures aimed at minimizing environmental impact.

Among the key trends shaping the future of PCB manufacturing is the focus on sustainable materials and processes. Companies are increasingly adopting eco-friendly alternatives in PCB design and production, such as biodegradable substrates and non-toxic chemicals. This transition not only meets stringent environmental standards but also appeals to a market that is progressively leaning towards sustainability. As a result, manufacturers that prioritize green practices are not only enhancing their market competitiveness but also contributing to a broader initiative of fostering a sustainable future in electronics.

The landscape of printed circuit board (PCB) design is experiencing a transformative shift, primarily driven by advancements in PCB design software. In 2025, these innovative tools are not just enhancing the speed of development but also elevating the precision of designs. Powerful simulation capabilities allow engineers to predict circuit performance under various conditions, significantly reducing the time spent on testing and revisions. This efficiency is critical for manufacturers looking to stay competitive in a rapidly evolving market.

Moreover, the integration of artificial intelligence and machine learning into PCB design software is revolutionizing the development process. These technologies are enabling the automation of routine tasks, allowing designers to focus on more complex challenges. Advanced algorithms can identify potential issues earlier in the design phase, which streamlines production and minimizes costly errors. As companies increasingly adopt these cutting-edge tools, we can anticipate a marked improvement in product reliability and an acceleration in time-to-market, making 2025 a pivotal year for the PCB industry.

| Trend | Description | Impact on Industry | Adoption Rate (%) |

|---|---|---|---|

| Flexible PCBs | Increasing use of flexible printed circuit boards in consumer electronics and medical devices. | Enhances device functionality and reduces size. | 45 |

| High-Frequency PCBs | Development of PCBs that can handle higher frequencies for telecommunications. | Supports advancements in 5G technology. | 60 |

| Advanced PCB Design Software | Utilization of AI and machine learning for PCB design optimization. | Increases development speed and reduces errors. | 70 |

| Eco-Friendly Materials | Shift towards environmentally sustainable materials in PCB production. | Lowers environmental impact and attracts eco-conscious consumers. | 50 |

| 3D Printing for PCBs | Increasing exploration of 3D printing technologies for PCB fabrication. | Promotes rapid prototyping and customized solutions. | 30 |

The impact of 5G technology on PCB design and functionality is profound, pushing the boundaries of what's possible in electronic manufacturing. As 5G networks expand, the demand for higher frequency and enhanced performance in printed circuit boards (PCBs) correspondingly increases. A report estimates that the global automotive PCB market will grow from USD 10.98 billion in 2025 to approximately USD 18.14 billion by 2034, reflecting the urgency for advanced PCB technologies that support 5G capabilities. As automotive applications increasingly rely on 5G, the need for specialized PCBs that can handle higher data rates and increased integration becomes critical.

Moreover, advancements like the development of novel wide-angle Rotman lens beamformers highlight the innovative direction of PCB design tailored for 5G mmWave applications. These designs not only aim to improve signal processing but also optimize the overall spatial performance of devices. The restructuring of PCB manufacturing processes to accommodate these innovations indicates an essential shift towards more complex and capable electronic architectures, positioning companies to remain competitive in the ever-evolving landscape of technology. As businesses prepare to adapt, understanding these trends is crucial for leveraging the full potential of PCBs in a 5G-dominated market.

As we approach 2025, the realm of printed circuit boards (PCBs) is experiencing a significant transformation, particularly in the areas of flexible and rigid-flex PCB technologies. These innovations are shaping the design and functionality of consumer devices, enabling them to become more compact and lightweight while maintaining high performance. The shift towards flexible PCBs allows for greater design freedom and adaptability, particularly in wearables and IoT devices that require unique form factors. This evolution aligns with consumer demand for products that are not only technologically advanced but also aesthetically pleasing and user-friendly.

Furthermore, rigid-flex PCBs are becoming increasingly popular in high-performance applications where space is at a premium. Combining the benefits of both rigid and flexible PCBs, they support more complex circuitry in a smaller footprint. As manufacturers seek to reduce size while increasing functionality, rigid-flex designs are ideal for smartphones, tablets, and other portable electronics.

The integration of advanced materials and manufacturing techniques promises enhanced durability and reliability, critical factors in today’s competitive market. As these trends continue to evolve, they will pave the way for a new generation of consumer devices that are smarter, thinner, and more versatile than ever before.

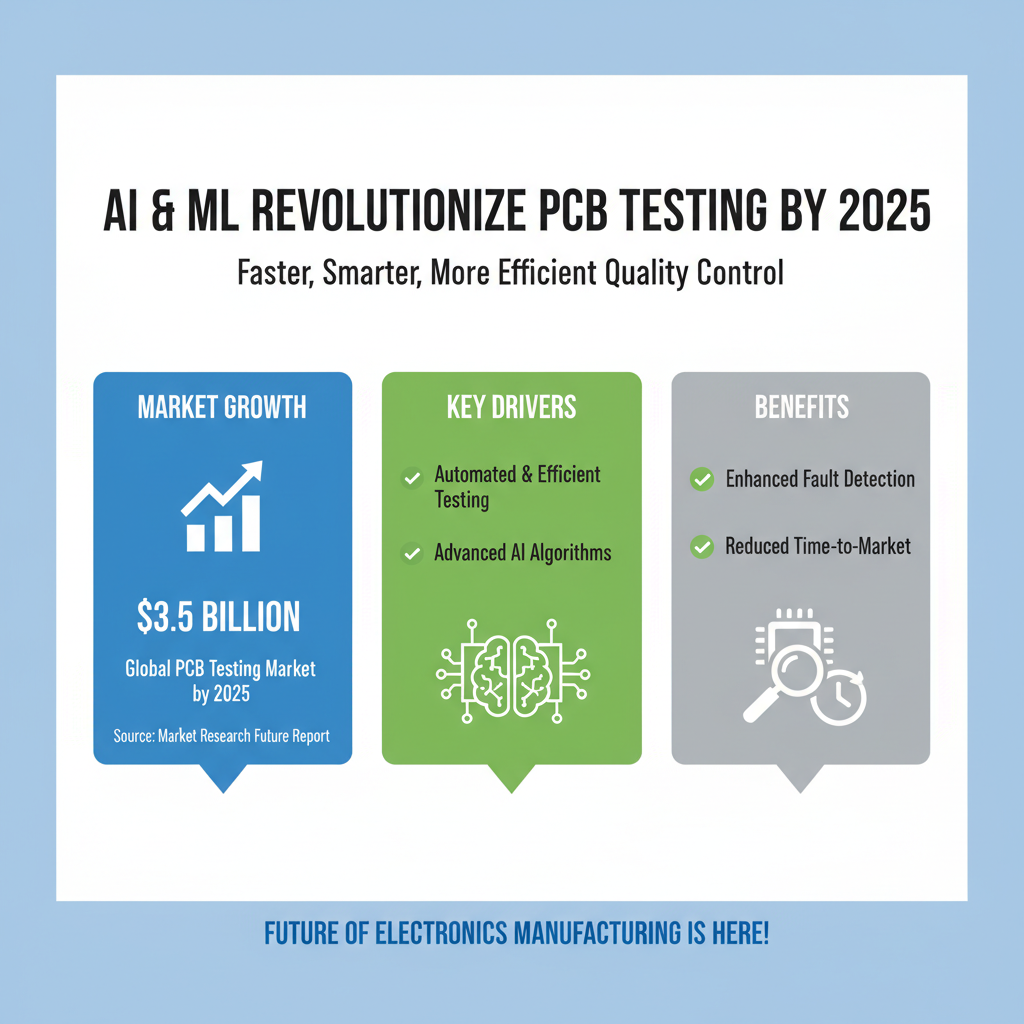

The integration of AI and machine learning in PCB testing and quality control is set to revolutionize the industry by 2025. According to a recent report from the Market Research Future, the global PCB testing market is projected to grow significantly, reaching approximately $3.5 billion by 2025. This increasing demand for automated and efficient testing methods is driving manufacturers to incorporate advanced AI algorithms. These technologies not only enhance fault detection but also optimize the testing processes, leading to reduced time-to-market for new products.

Moreover, AI-driven systems can analyze extensive datasets generated during the testing phase, identifying patterns that human inspectors might miss. This capability is crucial, as a study from the IPC (Association Connecting Electronics Industries) reveals that ineffective quality control can lead to defects costing manufacturers an estimated $12 billion annually. By leveraging machine learning, companies are expected to achieve higher accuracy levels and improve overall yield rates, reducing waste and saving costs. As we move toward 2025, the union of AI and PCB testing will undoubtedly set new benchmarks for quality assurance in electronics manufacturing.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |