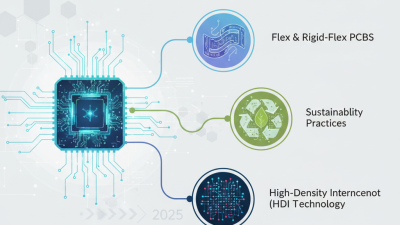

The demand for quick turn PCB manufacturing has surged in recent years, driven by the rapid evolution of technology and the necessity for faster prototyping and production processes. According to a report by industry experts, the global printed circuit board market is expected to reach $82 billion by 2025, with a significant portion attributed to quick turn capabilities. As industries strive for faster product development cycles, quick turn PCB services become a critical component, allowing companies to bring their innovations to market effectively and competitively.

In such a fast-paced environment, efficient and timely PCB manufacturing can significantly influence a company's bottom line. The ability to produce high-quality PCBs in a short timeframe not only meets market demand but also enhances operational efficiency. Research has indicated that organizations leveraging quick turn PCB services can reduce their time-to-market by approximately 30-50%, a factor that is increasingly vital in today's technology-driven landscape.

As we explore the top ten tips for achieving fast and efficient quick turn PCB manufacturing, it is essential for companies to consider key factors such as design optimization, material selection, and selecting the right manufacturing partner. These strategies not only streamline production but also ensure that the final product adheres to the required quality standards, ultimately positioning businesses for success in a competitive marketplace.

Quick Turn PCB manufacturing is a crucial aspect of modern electronics production, allowing companies to respond rapidly to market demands and technological advancements. This process emphasizes

speed and efficiency, enabling the rapid prototyping and production of printed circuit boards within tight timeframes. The significance of quick turn manufacturing lies in its ability to support innovation by allowing engineers and designers to iterate their products swiftly, test their functionality, and make necessary adjustments before mass production.

The importance of Quick Turn PCB manufacturing extends beyond mere speed; it also enhances competitiveness in the fast-paced electronics industry. By reducing lead times, companies can accelerate product development cycles and bring innovations to market ahead of competitors. This agility is particularly vital in industries such as telecommunications, automotive, and consumer electronics, where the rapid adoption of new technologies can significantly impact market share. Furthermore, quick turn capabilities often allow for a more flexible supply chain, accommodating last-minute design changes and catering to low-volume shipments without sacrificing quality. This flexibility can lead to improved customer satisfaction and long-term business relationships.

In the fast-paced world of electronics, rapid PCB (Printed Circuit Board) manufacturing has become essential for meeting market demands and reducing time-to-market for new products. Key factors influencing fast PCB production timeframes include design complexity, material selection, and production capabilities. According to industry reports, simplifying PCB layouts and utilizing standardized components can significantly expedite production, with studies showing that streamlined designs reduce manufacturing time by up to 40%.

Another critical factor is the selection of materials, as certain substrates and laminates may shorten processing times while still maintaining durability and performance. For instance, using high-speed materials can enhance signal integrity, which is crucial for modern applications. Data from market analyses indicate that choosing the right material can decrease production lead times by approximately 25%, thereby enhancing overall operational efficiency.

Furthermore, the capabilities of manufacturing equipment play a vital role. Advanced machinery, like automated manufacturing systems and advanced pick-and-place technology, can increase production speeds and accuracy. Reports highlight that companies employing state-of-the-art equipment report a 30% improvement in production efficiency. As the demand for quick turn PCB services continues to grow, addressing these key factors will be essential for manufacturers looking to stay competitive in a rapidly evolving market.

This chart illustrates the key factors affecting the efficiency and speed of PCB manufacturing processes. Each factor directly impacts the overall production timeline in a significant way.

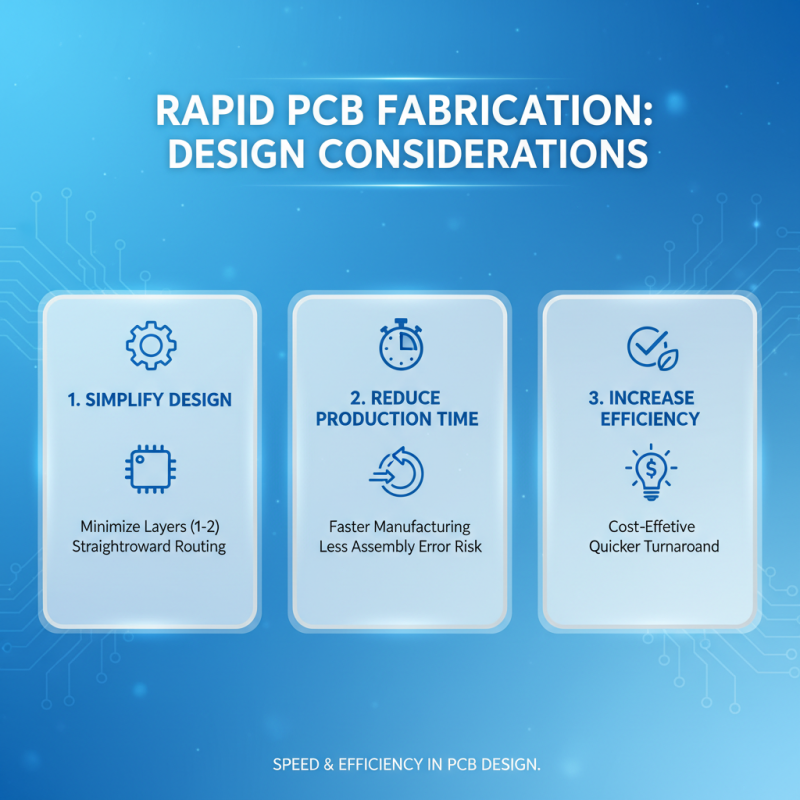

When embarking on a project that involves rapid PCB fabrication, understanding essential design considerations becomes critical for achieving both speed and efficiency. One of the key aspects is to keep the design simple. By minimizing the number of layers and using straightforward routing, designers can reduce production time. A single-layer or double-layer PCB not only speeds up the manufacturing process but also decreases the likelihood of errors during assembly.

Additionally, the choice of materials plays a significant role in quick turn PCB manufacturing. Opting for standard materials that are readily available can significantly cut down on lead times. For example, using FR-4 for the substrate is often recommended as it is commonly used and accepted in the industry. Furthermore, ensuring that design rules are met before the design is sent for fabrication can also expedite the process. Utilizing automated design rule checks can identify potential issues early on, leading to fewer delays in production.

Another vital tip is to incorporate testing pads within the design. This allows for easier testing and troubleshooting after production, thus reducing the overall turnaround time if any issues arise. By considering these essential design elements, manufacturers can enhance efficiency, leading to faster PCB delivery without sacrificing quality.

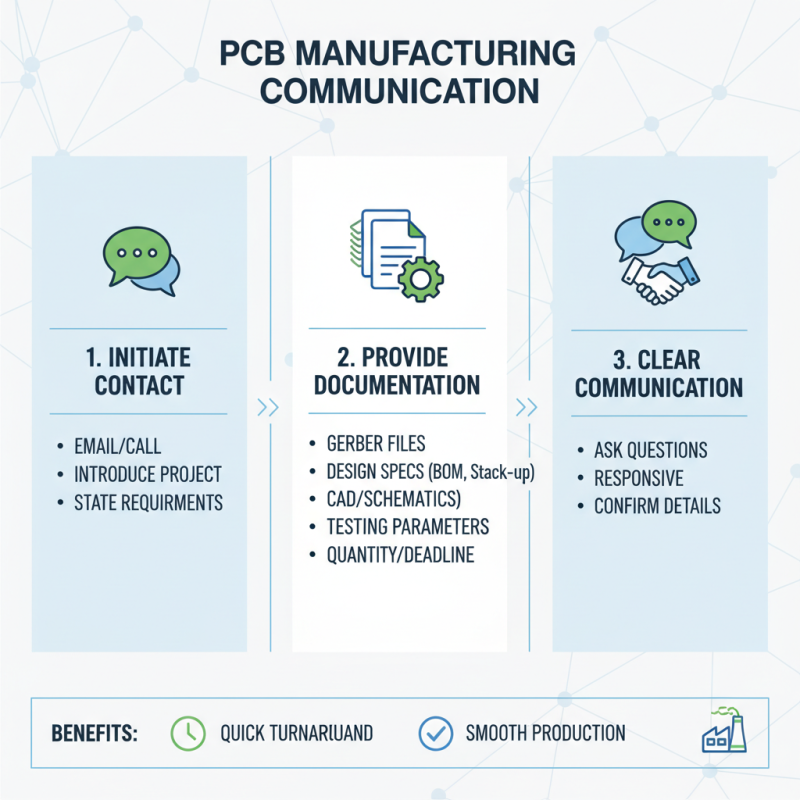

Effective communication with PCB manufacturers is crucial for ensuring quick turnarounds and a smooth production process. When initiating contact, it is essential to provide comprehensive design documentation. This includes Gerber files, design specifications, and any other relevant information that can help the manufacturer understand the project requirements clearly. Clear, concise communication minimizes misunderstandings and sets the foundation for a successful partnership.

Another important aspect of engaging with your PCB manufacturer is to establish open lines of communication. Regular updates and feedback throughout the manufacturing process can help catch potential issues early. Utilizing collaborative platforms or tools can facilitate real-time discussions and ensure that both parties are aligned. Moreover, being responsive to queries from the manufacturer can greatly enhance efficiency and speed up the production timeline, enabling faster delivery without compromising on quality.

Quality assurance is a critical component in quick turn PCB projects, as it ensures that the end products meet the required specifications and function as intended. One effective quality assurance measure is to conduct thorough design reviews before production begins. Engaging cross-functional teams can help identify potential issues early, allowing for timely modifications that save both time and resources. Implementing automated design checks can also help catch errors that may have been overlooked, thereby improving the overall reliability of the PCBs.

In addition to design reviews, regular testing throughout the manufacturing process is essential. Incorporating in-process inspections can help detect abnormalities at different stages, allowing manufacturers to rectify problems quickly. Another helpful tip is to establish clear communication channels among all stakeholders involved in the project. This ensures that any quality concerns are addressed promptly, which is particularly important in rapid turnaround scenarios.

By emphasizing quality assurance measures such as thorough inspections and proactive communication, manufacturers can significantly enhance the efficiency of quick turn PCB projects. This, in turn, helps maintain high standards, ensuring that all products meet or exceed customer expectations while adhering to tighter timelines.

| Tip Number | Tip Description | Expected Outcome |

|---|---|---|

| 1 | Utilize Advanced CAD Tools | Improved design accuracy and reduced time to prototype |

| 2 | Implement DFM and DFA Practices | Smoother manufacturing process and lower defect rates |

| 3 | Select the Right PCB Manufacturer | Faster turnaround times and better quality assurance |

| 4 | Schedule Regular Quality Checks | Early detection of issues leading to cost savings |

| 5 | Use Reliable Material Suppliers | Enhanced quality and performance consistency |

| 6 | Incorporate Automated Testing | Faster test cycles and higher precision in results |

| 7 | Maintain Clear Communication with Teams | Aligned goals and objectives, reducing errors |

| 8 | Train Staff Regularly on New Techniques | Continuously improving skills leading to better efficiency |

| 9 | Use Prototyping for Rapid Testing | Quicker feedback loops and faster adjustments |

| 10 | Establish Continuous Improvement Processes | Ongoing enhancements to quality and efficiency |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |