In the rapidly evolving world of technology, the demand for quality printed circuit boards (PCBs) continues to grow. With increasing complexity in electronic devices, choosing the right PCB manufacturer is essential. The USA hosts some of the top PCB manufacturers, known for their quality and innovation.

These companies play a vital role in various industries, from automotive to telecommunications. The term "pcb usa" represents not just a product, but a commitment to excellence. Each manufacturer brings unique strengths. Some excel in rapid prototyping. Others focus on high-volume production.

However, not all manufacturers may meet every business need. Companies must evaluate quality, lead time, and cost carefully. The best choice often involves balancing these factors. This guide highlights ten prominent PCB manufacturers in the USA, providing insights into their offerings. Understanding their capabilities can help in making informed decisions.

The PCB manufacturing industry in the USA plays a crucial role in the electronics sector. The market size reached approximately $9 billion in 2022. This growth reflects increasing demand for electronic products across various sectors, including automotive and consumer electronics. However, this sector faces challenges. Supply chain disruptions have impacted production timelines.

Labor shortages are another hurdle. Many companies are struggling to find skilled workers. According to a recent survey, up to 40% of manufacturers reported difficulties in hiring qualified personnel. Additionally, rising material costs have raised concerns. Manufacturers often need to balance quality and affordability. Innovations in technology, such as automation, offer potential solutions. Yet, implementing these technologies requires investment and expertise.

Environmental regulations are also increasing. Companies must adopt sustainable practices while maintaining efficiency. Adapting to stricter guidelines is essential. However, compliance can involve significant costs. As the industry evolves, continuous improvement is necessary. Embracing change could help meet future demands.

This bar chart illustrates key performance metrics in the PCB manufacturing industry in the USA, including revenue, manufacturing capacity, and number of employees. This data provides a snapshot of the industry's scale and resources.

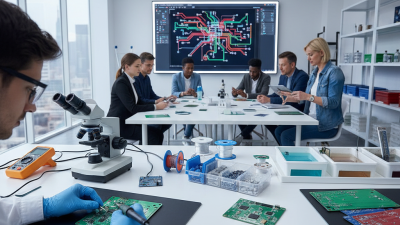

When considering PCB manufacturing quality and innovation, several key factors come into play. First, raw material selection is crucial. High-quality materials ensure durability and functionality. Suppliers should be reliable and adhere to strict standards. This choice affects the overall performance of the printed circuit boards.

Manufacturing processes also significantly impact quality. Advanced techniques, such as automated assembly and precision etching, enhance accuracy. However, not all manufacturers implement these processes effectively. It’s essential to verify their equipment and capabilities. This can sometimes be overlooked but is vital for achieving consistency.

Tips: Always ask about testing procedures. Rigorous quality assurance checks lead to fewer defects. Regular assessments of the production line can help identify inefficiencies. Never settle for superficial measures; deeper evaluations can yield better feedback. Remember, innovation often stems from creativity and experimentation. Encouraging teams to explore new ideas can lead to breakthroughs.

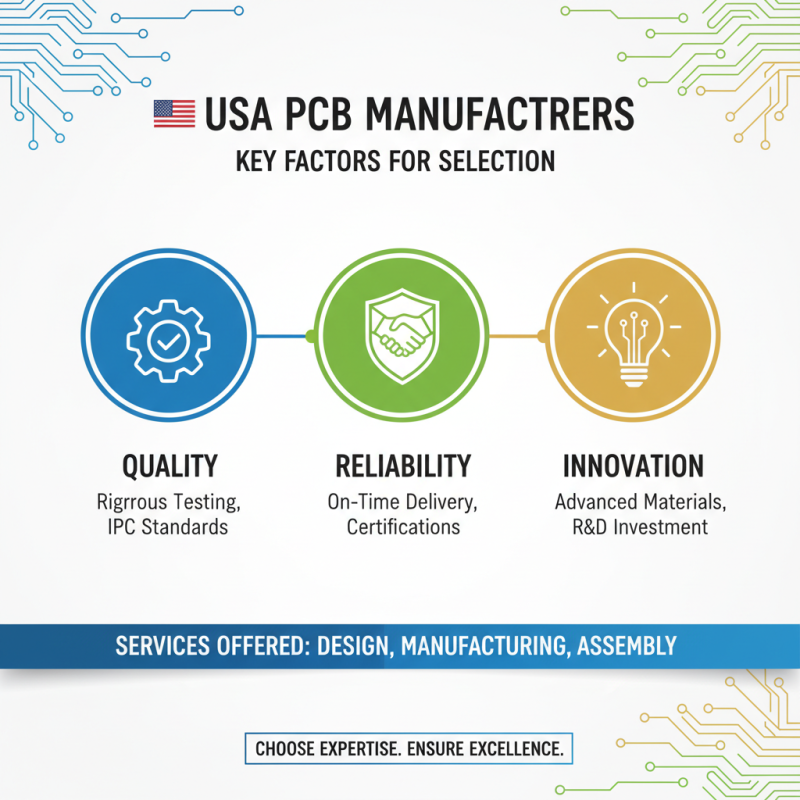

When searching for top PCB manufacturers in the USA, a few key factors come to play. Quality, reliability, and innovation stand out. Many PCB manufacturers have made remarkable strides in recent years. They offer a range of services, from design to manufacturing. Yet, not all provide the same level of expertise. It's crucial to assess each company's capabilities before making a decision.

Some manufacturers excel in rapid prototyping. This can greatly speed up the development process. Others focus on high-volume production. However, they might lack flexibility. It’s important to find a balance between speed and quality. Be aware that not every company maintains the same standards throughout all projects. Some might meet expectations on small orders, but performance can drop on larger scales.

Investing time in research can pay off. Look for case studies and customer reviews. Engaging directly with manufacturers can reveal how they handle challenges. This insight is necessary to make informed choices. Many companies are eager to showcase their successful projects. But, a deep dive into their processes can uncover potential pitfalls. It's essential to stay vigilant in this ever-evolving landscape.

When exploring the landscape of PCB manufacturers in the USA, the variety of services offered remains a crucial factor. Many companies provide standard PCB design and fabrication, but the best ones go beyond basic services. They might offer rapid prototyping, which is essential for companies needing quick turnarounds. According to industry reports, 70% of firms now require shorter lead times than just five years ago. This shift has forced manufacturers to adapt and innovate.

Furthermore, quality control is a vital aspect of service offerings. High-standard manufacturers implement rigorous testing protocols. These can include electrical testing, thermal analysis, and reliability assessments. A recent survey indicated that 80% of clients prioritize reliability and quality over pricing. Yet, it's concerning that not all manufacturers consistently meet these expectations. Inconsistent quality can lead to significant project delays or failures.

In addition, some companies offer design support and consultation, which can be invaluable for clients unfamiliar with PCB complexities. Collaborating closely with engineers helps avoid costly mistakes. Yet, the availability of such services is often not well advertised. It’s a missed opportunity for firms seeking comprehensive support throughout the design and manufacturing process. As the industry continues to evolve, understanding these service dimensions becomes increasingly important for businesses aiming for success.

| Manufacturer | Year Established | Specialization | Max Layer Count | Lead Time | Minimum Order Quantity |

|---|---|---|---|---|---|

| Manufacturer A | 1985 | High-Tech PCBs | 20 Layers | 2 Weeks | 5 Units |

| Manufacturer B | 1990 | Flex PCBs | 12 Layers | 3 Weeks | 10 Units |

| Manufacturer C | 1995 | Rigid PCBs | 18 Layers | 4 Weeks | 20 Units |

| Manufacturer D | 2000 | Multi-layer PCBs | 24 Layers | 5 Weeks | 15 Units |

| Manufacturer E | 2010 | High-Frequency PCBs | 10 Layers | 1 Week | 1 Unit |

| Manufacturer F | 2015 | Low-Cost PCBs | 8 Layers | 2 Weeks | 50 Units |

| Manufacturer G | 2005 | Prototype PCBs | 6 Layers | 1 Week | 5 Units |

| Manufacturer H | 2012 | Industrial PCBs | 16 Layers | 3 Weeks | 20 Units |

| Manufacturer I | 1998 | Automotive PCBs | 14 Layers | 4 Weeks | 25 Units |

| Manufacturer J | 2020 | Consumer Electronics PCBs | 10 Layers | 1 Week | 2 Units |

The PCB manufacturing sector in the USA is evolving rapidly. New materials and technologies emerge every year. Companies now focus on sustainability, reducing waste in the production process. Many are investing in eco-friendly materials. This shift addresses environmental concerns and consumer demand for greener products.

Automation is also a key trend. Advanced robotics are taking over repetitive tasks. This reduces human error and boosts production speed. However, the reliance on automation raises questions. How will this affect employment in the industry? Workers might need to adapt to new skill sets in this evolving landscape.

The need for smaller, more complex circuits is growing. As electronics shrink, PCBs must follow suit. This presents challenges in design and manufacturing. Companies must improve their precision. Mistakes in such small components could be costly. Manufacturers are exploring innovative solutions, yet issues still arise in balancing quality and efficiency. Cultivating a culture of continuous improvement is crucial for future success.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |