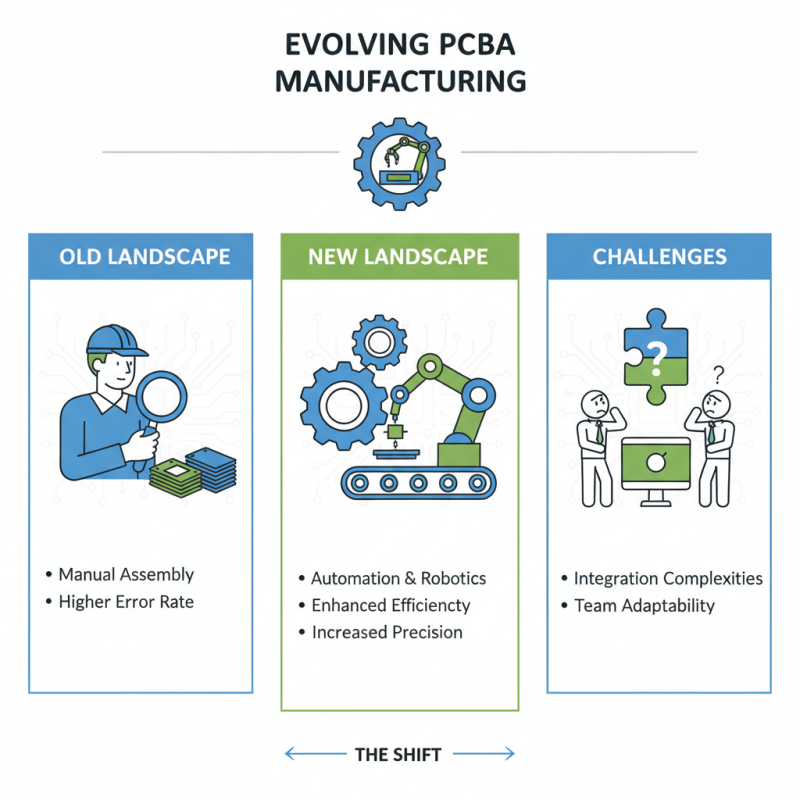

The landscape of PCBA manufacturing is evolving rapidly. As we look toward 2026, several emerging trends promise to reshape the industry. According to a recent report by Market Research Future, the global PCBA market is expected to reach USD 100 billion by 2026, reflecting a compounded annual growth rate of 10%. This growth signals not just opportunity but also challenges that manufacturers must navigate.

John Smith, a leading expert in PCBA manufacturing, states, "Innovation and agility are crucial for success in this field." This sentiment resonates as automation and AI-driven solutions gain traction. While these technologies offer efficiency, they create new complexities in production workflows. Balancing speed and quality becomes increasingly difficult, demanding strategic reassessment.

Furthermore, sustainability is no longer an option in PCBA manufacturing; it is essential. Companies must rethink materials and processes to reduce environmental impact. Despite these pressures, many manufacturers may still cling to outdated practices. Embracing change and improving operational transparency remains a significant hurdle. As we delve deeper into the top trends, it's clear that adaptation, rather than complacency, will define the future of PCBA manufacturing.

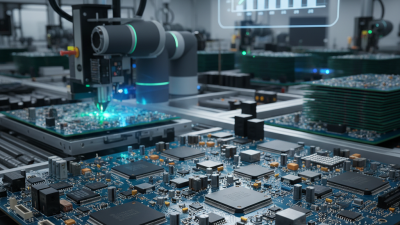

In 2026, emerging technologies will drastically reshape PCBA manufacturing. Automation stands at the forefront. Many companies now implement advanced robotics for assembly lines. According to a recent industry report, over 45% of firms are expected to adopt such automation. This shift enhances efficiency but raises concerns over workforce displacement.

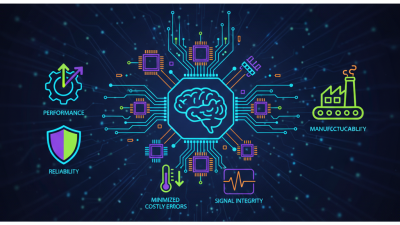

Another critical trend is the integration of artificial intelligence (AI). AI algorithms optimize production processes, minimizing errors and waste. Data from industry surveys indicates that 35% of manufacturers are investing in AI technology for predictive maintenance. However, the reliance on AI poses questions about long-term skills required for workers.

Additionally, sustainable practices are gaining traction. The demand for eco-friendly materials is rising. Research shows that companies prioritizing sustainability can see a 25% boost in customer loyalty. Yet, achieving true sustainability remains a challenge. Finding reliable, green alternatives for traditional materials is still a work in progress. Overall, while these technologies promise significant advancements, they also bring complex dilemmas for the future of PCBA manufacturing.

Sustainable practices are transforming the PCB assembly industry. Companies are increasingly adopting eco-friendly methods to reduce their carbon footprint. According to a recent industry report, over 50% of PCB manufacturers plan to implement sustainable practices by 2026. This shift reflects a growing awareness of environmental issues among stakeholders.

Recycling of materials plays a crucial role. By reusing metals and plastics, manufacturers can significantly lower waste. Studies indicate that adopting sustainable materials can reduce production costs by up to 30%. This is important for companies looking to balance quality and cost. However, the transition to greener practices isn't without challenges. Sourcing sustainable materials can be difficult, and many companies face supply chain disruptions.

Energy-efficient production methods are also gaining traction. Many PCB assembly firms are investing in advanced machinery that consumes less power. Reports reveal that energy-efficient processes can cut costs by 20% over five years. Yet, some companies hesitate due to the upfront investment. They may wonder if the long-term savings are worth the initial expense. The journey towards sustainability in PCB manufacturing is complex and requires careful consideration.

The landscape of PCBA manufacturing is evolving. Automation and robotics are becoming crucial components. These technologies enhance efficiency and precision in production. Automated processes reduce human error and speed up assembly. However, integration can pose challenges. Not all teams might be ready for this shift.

Robotics streamline tasks such as soldering and inspection. High-speed robots perform these operations with precision. This transition requires training staff to work with new systems. Resistance to change can hinder progress. It's essential to address these concerns openly.

Tips: Embrace gradual changes. Train employees at every stage. Regularly assess the effectiveness of automated systems. Monitor for potential issues. Continuous improvement is key in this fast-paced environment. Investing in technology is important. But remember, human insight is irreplaceable. Balancing both can lead to better outcomes.

The Internet of Things (IoT) is transforming PCBA manufacturing. Smart devices collect crucial data in real-time. This data helps improve efficiency and quality. According to a recent report, companies incorporating IoT have seen a productivity increase of 15%. Sensors monitor equipment performance, minimizing downtime. This leads to better output.

However, the integration of IoT isn't without challenges. Many manufacturers face difficulties in data management. Security concerns arise from connecting devices. A survey indicated that 40% of firms worry about data breaches. Moreover, the investment in IoT technologies can be significant. Smaller companies may struggle to keep up.

Despite the hurdles, the benefits are significant. IoT enhances traceability in the production line. It allows for immediate response to any inconsistencies. With predictive analytics, manufacturers can anticipate issues. This proactive approach results in fewer defects and higher quality. The shift towards IoT in PCBA manufacturing is clear, but careful implementation is essential.

| Trend | Description | Impact on Efficiency | Quality Improvement |

|---|---|---|---|

| IoT Integration | Using IoT devices to monitor the manufacturing process in real-time. | Increases operational efficiency by reducing downtime. | Helps in early detection of defects. |

| Automation | Implementing automated systems for assembly and inspection. | Reduces labor costs and increases production speed. | Improves consistency in quality control. |

| AI and Machine Learning | Utilizing AI for predictive maintenance and quality assurance. | Enhances decision-making and operational effectiveness. | Significantly reduces error rates. |

| Sustainability Practices | Focus on environmentally friendly materials and processes. | Improves resource efficiency and reduces waste. | Lead to higher quality sustainable products. |

| Cloud Computing | Storing and processing manufacturing data in the cloud. | Facilitates data accessibility and collaboration. | Enables improved data analysis for quality assurance. |

As the demand for advanced electronics continues to grow, so does the need for innovative PCBA designs. According to a recent market report, the global PCB assembly market is projected to reach $80 billion by 2026, driven largely by consumer electronics and automotive sectors. This surging demand pushes manufacturers to adopt smart technologies. However, the integration is not without its challenges. Many facilities struggle with outdated processes that hinder responsiveness.

Sustainability is also becoming a critical driver in PCBA manufacturing. A study from the Electronics Industry Citizenship Coalition highlights that 75% of consumers prefer brands focused on sustainability. In response, companies are exploring eco-friendly materials and waste reduction methods. Despite these efforts, many manufacturers still face difficulties in achieving significant sustainability targets. This gap reveals a need for ongoing improvement and commitment to change within the industry.

The complexity of modern designs further complicates manufacturing. With increasingly miniaturized components, assembly precision is non-negotiable. Research indicates that 40% of defects arise from assembly errors. As manufacturers address these precision challenges, a clear need for enhanced training and technology integration surfaces. The journey toward innovation in PCBA is ongoing, filled with opportunities and room for growth.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |